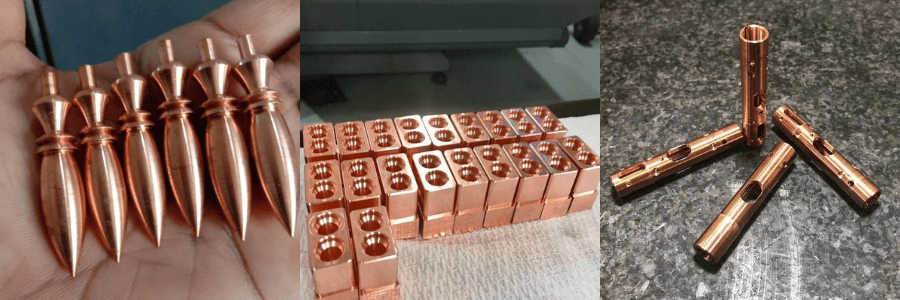

Copper Turned Components Manufacturer

Copper Turned Components/Copper Turned Components Manufacturer/Copper Turned Components Supplier/Copper Turned Components wholesaler/Best Quality of Copper Turned Components/

Introduction

Vision Turning Components – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned components Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality. We are the best Copper Turned Components Supplier.

Because of their superior thermal characteristics, corrosion resistance, and electrical conductivity, copper-turned components are essential to many different sectors. Best Quality of Copper turned components are vital to many industries, including telecommunications, automotive, and plumbing systems. This blog will discuss copper turned components, their uses, the production process, and why it’s important to pick the best manufacturer for your requirements.

Vision Turning Components (VTC) is a well-known brand you can count on if you’re searching for a dependable producer of copper turned components. With years of expertise and a dedication to quality, VTC offers premium copper turned components that are customised to meet your industry’s needs.

What are Copper Turned Components?

Using a lathe, copper rods or bars are turned into precision-machined parts known as copper turned components. CNC (Computer Numerical Control) machinery is used in the manufacturing of these components to guarantee exact dimensions and constant quality. Because of its many good qualities, including strong electrical conductivity, thermal stability, and corrosion resistance, copper is utilised widely. Turned components are perfect for industries like electronics, electrical, automotive, and telecommunications because they are frequently employed in situations that ask for precise and complex geometries.

Applications of Copper Turned Components

Due to its remarkable qualities, copper-turned components are used in many different industries. These are a few examples of common uses:

1. The Electronics and Electrical Sector

Because of its superior electrical conductivity, copper is favoured in the electronics and electrical sectors. Components with copper turns are utilised in:

- electrical connections

- Terminals

- Switchgear components

- Parts of a circuit breaker

- Relays

2. Plumbing and HVAC Systems

Copper is perfect for plumbing and HVAC (Heating, Ventilation, and Air Conditioning) systems because of its malleability and resistance to corrosion. Turned components including fittings, valves, and couplings are employed in plumbing systems to ensure reliable performance.

3. Automobile Sector

Copper turned components are used widely in the automotive sector for a variety of purposes. Among them are:

- Senses

- components of fuel injectors

- terminals for batteries

- Components of the cooling system

4. Telecommunications

Copper-turned components are utilised in the production of connectors, cable terminals, and other parts that need to be exceptionally strong and precise.

5. Tools for Industry

Industrial machinery also uses copper-turned components for a variety of applications, including fluid handling systems, electrical connections, and parts that need to have a high heat conductivity.

Benefits of Using Copper Turned Components

Numerous businesses choose copper-turned components because of their various advantages. Among these advantages are:

- Elevated Electrical Conductivity

Copper is perfect for use in electrical applications since it has one of the highest electrical conductivities of any metal. Turned copper parts minimise energy loss and offer effective current flow. - Thermoelectric Properties

Copper is a good choice for heat transfer applications like heat exchangers and cooling systems because of its excellent thermal conductivity. - Resistance to Corrosion

Because copper is naturally resistant to corrosion, turned components can serve a long time. This is especially important for applications that are subjected to chemicals or moisture. - Flexibility and Sturdiness

Because copper is flexible and malleable, it may be easily shaped into complicated shapes without losing its strength. It’s a great option for precisely turned components because of this. - Economy of Cost

When compared against other materials, copper is more affordable, especially when taking into account its performance, longevity, and low maintenance needs.

Why Choose Vision Turning Components (VTC): Best Copper Turned Components Manufacturer

Choosing the correct manufacturer for copper turned components is essential to assure quality, reliability, and timely delivery. We are the best Copper Turned Components Supplier. For all of your demands involving copper turned components, Vision Turning Component (VTC) is the best option for the following reasons:

- Skill and Knowledge

With years of experience in the field, VTC has the knowledge to produce superior copper turned components that satisfy the demands of different industries. Our talented engineers and technicians are dedicated to providing each component with accuracy and high quality. - Cutting-Edge CNC Equipment

At VTC, we employ innovative CNC machinery to guarantee the highest standards of consistency and accuracy in our output. To satisfy our clients’ needs, we have the newest technology in our state-of-the-art manufacturing facilities. We are the best Copper Turned Components wholesaler. - Personalisation

We are aware that every industry has particular needs. We provide customised options in order to address the unique requirements of our clients. VTC is dedicated to offering the right product for your application, regardless of the complexity of the design or the need for a particular finish. - Assurance of Quality

At VTC, quality is our first concern. Every step of the manufacturing process is subject to strict quality control procedures, which help us guarantee that the copper turned components we produce satisfy international requirements. Our quality control team measures each component’s size, surface finish, and other important characteristics using advanced measuring tools. - Reasonable Prices

At VTC, we’re dedicated to offering premium goods at affordable costs. We are able to provide affordable solutions without sacrificing quality because to our effective manufacturing procedures and large-scale production capacity. - Prompt Delivery

We are aware of the importance that prompt delivery is in the busy industrial setting of today. We always guarantee that our customers receive their goods on schedule thanks to our effective supply chain management. - Client Assistance

Delivering high-quality products is just one part of our dedication to client pleasure. We offer first-rate customer service, from aiding with product selection to helping with after-sales support. Our staff is available at all times to respond to your enquiries and worries.

Industries Served by Vision Turning Components (VTC)

Our premium copper turned components at Vision Turning Component (VTC) serve a variety of industries. Among the sectors we cater to are the following:

- Electronics and electrical

High electrical conductivity and precision are required for the components we make for electrical connectors, terminals, and switchgear parts. - Automobile:

We utilise our copper-turned components in battery terminals, gasoline injectors, sensors, and other automobile applications. - Heating and plumbing

We offer copper-turned fittings, valves, and couplings—components that are resistant to corrosion and permanent—for HVAC and plumbing systems. - Telecommunications:

We employ our components to make cable terminals, connectors, and other precision parts in the telecommunications industry. - Industrial Machinery:

For industrial machinery that needs strong thermal conductivity, we provide copper turned components.

Conclusion: Copper Turned Components Manufacturer

Many industries, such as the electrical, automotive, plumbing, telecommunications, and industrial machinery sectors, depend on copper-turned components. They are perfect for precision applications because of their superior thermal characteristics, resistance to corrosion, and electrical conductivity.

Regarding copper turned component manufacturers, Vision Turning Components (VTC) is a dependable and knowledgeable supplier. You should turn to VTC if you’re looking for high-quality copper turned components because of their advanced CNC machinery, strict quality control procedures, and dedication to client satisfaction. We are the best Copper Turned Components wholesaler.

VTC has the knowledge and resources to provide the perfect match for your application, regardless of whether you require standard or customised components. Speak with Vision Turning Components (VTC) right now to go over your needs and see how our superior quality and service compare.