Stainless Steel Turned Components Manufacturer

Table of Contents

Introduction

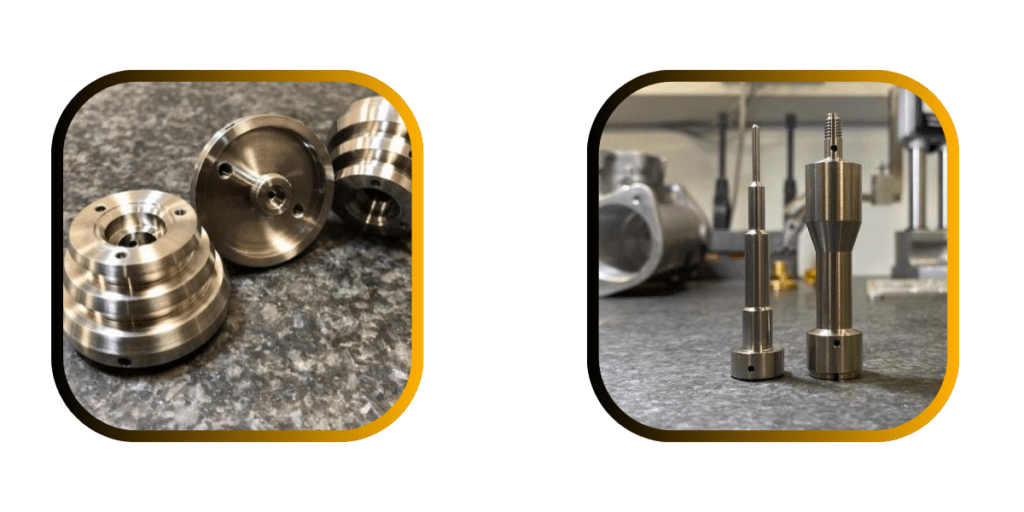

Vision Turning Component – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned components Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality. We are the best stainless steel turned componts supplier.

Stainless steel turned components are essential to many different businesses in the manufacturing and engineering fields. These parts are crucial for maintaining the durability, effectiveness, and functionality of machinery and systems in the automotive and aerospace industries. Selecting the appropriate manufacturer is essential to getting the best outcomes as the need for precise and high-quality parts rises.

One of the top manufacturers of ss turned components, Vision Turning Component, offers top-notch goods that are renowned for their exceptional quality, accuracy, and longevity. This post will explain what ss turned components are, how they are used, and why selecting Vision Turning Component could revolutionise your company.

What Are Stainless Steel Turned Components?

Components constructed of stainless steel that have undergone a turning process to shape and customise them are known as stainless steel turned components. The machining process of turning involves rotating a part while applying a cutting tool to it in order to remove material and shape the component to meet predetermined parameters.

Modern CNC (Computer Numerical Control) equipment is used to create these parts, guaranteeing excellent accuracy, precision, and repeatability. For a variety of turned components,ss is the material of choice due to its strength, resistance to corrosion, and adaptability.

Types of Stainless Steel Turned Components

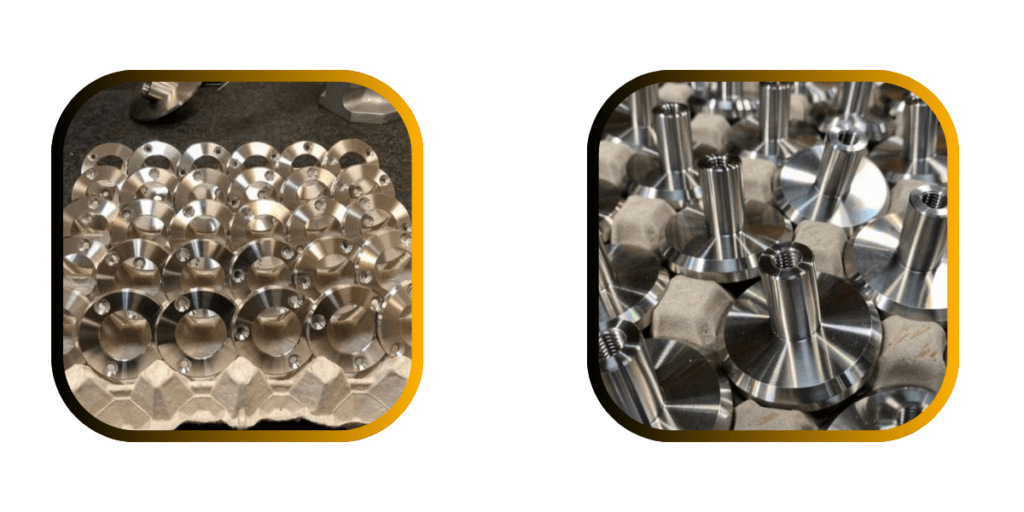

A wide range of turned stainless steel components are produced to satisfy particular industrial requirements. Typical varieties include:

- Nuts and bolts

These are necessary fasteners for usage in the automotive, construction, and other industries. Because of its exceptional durability and corrosion resistance, stainless steel bolts and nuts are perfect for tough outdoor settings. - Spacers and washers

The purpose of washers and spacers is to disperse a fastener’s weight and shield surfaces from harm. The integrity of mechanical assemblies depends on stainless steel washers and spacers. - Valves

In piping systems, ss valves—such as check, gate, and ball valves—are crucial for managing the flow of gases and liquids. They are ideal for sectors like chemical processing and oil and gas because of their resistance to rust and corrosion. - Flanges

Mechanical parts called flanges are used to join pipelines, valves, and other devices. Because of its strength and capacity to tolerate high pressure, stainless steel flanges are frequently utilised in industries like water treatment, chemical, and power plants. - Shafts

Shafts are a vital component of many types of machinery and are used to convey rotational force. Shafts made of ss are robust and made to function flawlessly under a variety of circumstances.

Applications of Stainless Steel Turned Components

Because of the material’s strength and resistance to corrosion, stainless steel turned components are used in practically every industry. The following are a few typical industries that use turnedss components:

- Automobile Sector

Brake systems, engines, exhaust systems, and suspension components are just a few of the aspects in the automotive industry that use stainless steel turned components. These components are essential to making sure cars run well and endure for many years. - The Aeronautical Sector

High-performance parts that can tolerate harsh temperatures and conditions are required by the aerospace sector. Aircraft engines, landing gear, and other critical systems use stainless steel turning parts like bolts, shafts, and valves. - The Marine Sector

ss is the preferred material for maritime applications due to its ability to withstand corrosion from saltwater. Propellers, pumps, and marine valves are examples of turned parts that are crucial to maintaining ship and vessel functionality in challenging conditions. - The Gas and Oil Sector

Components for the oil and gas sector must be able to withstand corrosive substances, high pressures, and extremely high temperatures. Flanges, valves, and pumps are examples of stainless steel turned parts that are made to withstand these difficulties while maintaining dependability and safety. - Health Care Sector

Stainless steel is utilised in the medical industry to make parts for equipment, implants, and surgical tools. The performance and accuracy necessary for medical applications are provided by turned components.

Why Choose Stainless Steel for Turned Components?

For a number of reasons, stainless steel is one of the most popular materials utilised in the production of turned components.

- Resistance to corrosion

Stainless steel is perfect for parts exposed to hostile conditions because of its exceptional resistance to rust, corrosion, and tarnishing. Stainless steel is unaffected by moisture, chemicals, or extremely high or low temperatures. - Sturdiness

Because of its exceptional strength and durability, stainless steel can be used in applications that call for long-lasting functionality. Because of its ability to tolerate high pressure and stress, the components will continue to function at their best throughout time. - Visual Appeal

Components made of stainless steel have a beautiful sheen that makes them look good. They are also simpler to clean and maintain because of their glossy finish and smooth surface. - Resistance to Wear and Tear

Even when used extensively, stainless steel is renowned for its ability to withstand wear and tear. Because of this, it is ideal for use in sectors like manufacturing and the automobile industry where parts are constantly under pressure and friction. - Properties That Are Not Reactive

Stainless steel is very useful in sectors like chemical engineering, food processing, and pharmaceuticals because it doesn’t react with most chemicals or conditions.

Why Vision Turning Component?

When it comes to high-quality stainless steel turned components, Vision Turning Component stands out as a reputable and trusted producer. Our knowledge, attention to detail, and devotion to quality set us apart from others in the business.

- Accuracy and Precision

Modern CNC turning machines are used at Vision Turning Component to create components with extreme precision. We guarantee that every item satisfies the highest industry requirements, whether you require conventional components or custom-made parts. - A Vast Selection of Items

We have a large selection of turned stainless steel parts, such as shafts, washers, nuts, bolts, and more. Our product line serves a wide range of industries, guaranteeing that our customers will receive the parts they require for their particular uses. - Personalisation

We are aware that every industry has different requirements. Our staff collaborates closely with customers to provide specialised solutions for unique parts that satisfy particular needs. We offer specialised services to give precisely what you require, whether it be in terms of coatings, finishes, or proportions. - Assurance of Quality

At the core of what we do is quality. To guarantee that every component satisfies international standards, we follow stringent quality control methods at every stage of the manufacturing process. We have a reputation for dependability and excellence because to our dedication to quality. - Prompt Delivery

We are aware of how crucial deadlines are in industrial and manufacturing settings. Your orders will always be delivered on schedule thanks to our optimised logistics and effective production procedures. - Economical Remedies

Our goal at Vision Turning Component is to give you the most return on your investment. We are an affordable option for all of your stainless steel turned component needs because of our affordable prices and premium products. - Skilled Group

To provide the best goods, our team of highly qualified engineers, machinists, and quality inspectors collaborates. Our years of experience in the industry have given us the know-how to manage even the most challenging needs.

Conclusion

For industries that need parts that are corrosion-resistant, long-lasting, and high-performing, stainless steel turned components are essential. As one of the top producers of these vital parts, Vision Turning Component offers precisely developed parts to a wide variety of sectors. We are the best stainless steel turned components exporter.

Vision Turning Component is your perfect partner for all of your stainless steel turned component needs because of their dedication to quality, client happiness, and prompt delivery. Our staff is available to offer solutions that guarantee the smooth and effective operation of your machines and systems, whether you require standard goods or custom components.

For all of your needs involving stainless steel turned components, get in touch with us right now.