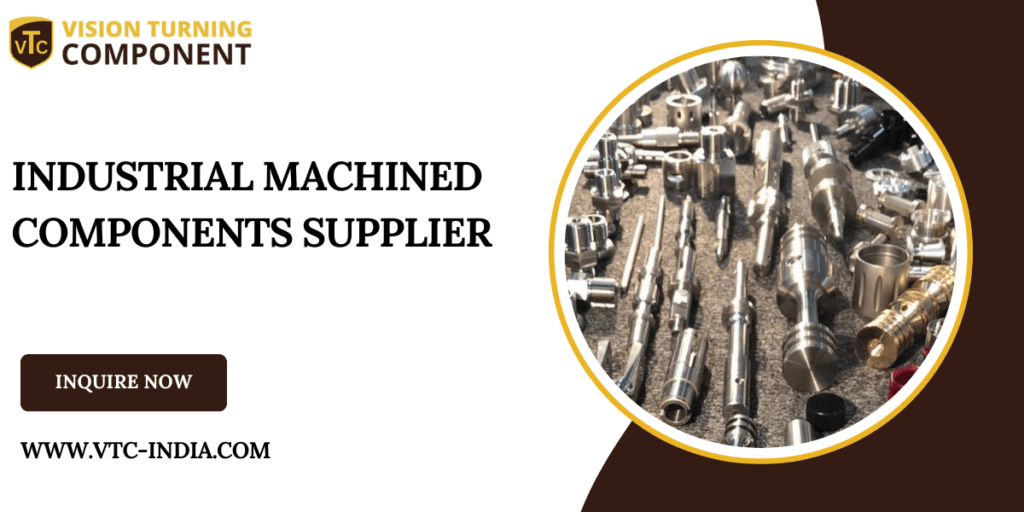

Industrial Machined Components Supplier

Industrial Machined Components Supplier | Industrial Machined Components Manufacturer | Industrial Machined Components Provider | Exporter of Industrial Machined Components

Introduction

VTC India, an Industrial Machined Components Manufacturer, has built a name as a leading manufacturer of industrial machinery components in Gujarat. VTC India has supplied great goods and services for years, thanks to its extensive experience and devoted team of specialists. The company’s commitment to excellence, client satisfaction, and continual progress distinguishes it from competitors.

Precision and dependability are essential components of achievement in the fast-paced world of industrial manufacturing. The quality and consistency of its components serve as the industry’s backbone, making industrial machined components suppliers critical stakeholders. These companies provide critical components that improve the performance and efficiency of machinery and equipment in a variety of sectors. This article discusses the importance of industrial machined components, the role of suppliers in the manufacturing ecosystem, and how Vision Turning Component, a prominent supplier in the industry, represents excellence in this area.

The Importance of Industrial Machined Components

What Are Industrial Machined Components?

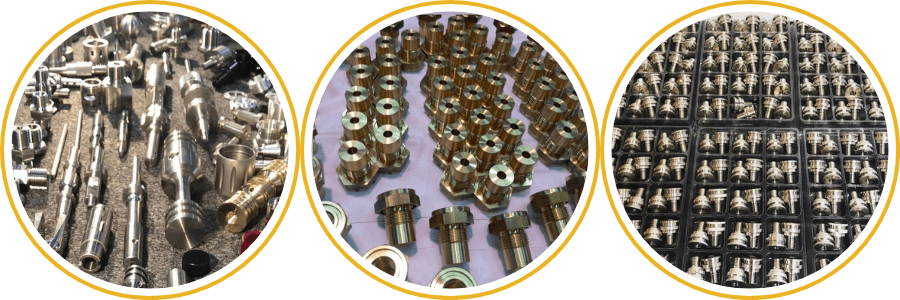

Industrial machined components are precision-engineered parts made by milling, turning, drilling, and grinding. These components are essential for the assembly of machinery and equipment used in several industries, including automotive, aerospace, oil and gas, electronics, and others. Gears, shafts, bearings, fasteners, and special pieces tailored to specific needs are examples of machined components.

Precision in Manufacturing

The precision of industrially machined components is essential. Even the smallest variation from the stated dimensions can result in equipment failure, increased wear and tear, and compromised safety. As a result, suppliers must use severe quality control systems, including innovative machinery and expert personnel, to verify that each component meets exacting standards.

The Function of Industrial Machined Components in Different Industries

- Machined components are used in engines, transmissions, brake systems, and other automotive applications. The dependability of these components is essential for vehicle safety and performance.

- The aerospace industry relies on high-precision machined components for aircraft engines, landing gear, and structural sections. The harsh conditions under which these components operate necessitate the highest levels of precision and durability.

- Oil and Gas Industry: Machined components are used in drilling equipment, pumps, and valves. These components must tolerate extreme conditions, such as high pressure and caustic substances.

- The electronics sector requires small, intricately machined components for gadgets like as smartphones, computers, and medical equipment. Precision and miniaturization are important factors in this field.

Challenges for Industrial Machined Components Supplier

Meeting Stringent Quality Standards

Suppliers of industrial machined components must traverse a complicated web of quality standards and certifications. These standards, including ISO 9001 and AS9100, ensure that suppliers consistently produce high-quality products. Obtaining and keeping these certifications necessitates a dedication to continual improvement, stringent quality control procedures, and regular audits.

Managing Supply Chain Complexity

Suppliers frequently collaborate with clients from multiple regions due to the global nature of production. This raises logistical, lead-time, and communication issues. Suppliers must have strong supply chain management processes in place to ensure timely delivery and manage risks such as supply chain disruptions or material cost variations.

Adapting To Technological Advances

The manufacturing business is fast changing, with advances in automation, artificial intelligence, and additive manufacturing (3D printing) transforming component production. Suppliers must stay current on technical trends and invest in cutting-edge machinery and software to remain competitive.

Customization and Flexibility

Clients are increasingly demanding bespoke solutions to fit their individual requirements. Suppliers must be adaptable and capable of creating small-batch or prototype components while maintaining quality and efficiency. Balancing the demand for personalization against economies of scale is a big challenge for suppliers.

Vision Turning Component: Industrial Machined Components Supplier

Overview of Vision Turning Component

Vision Turning Component is a leading provider of industrial machined components, recognized for its dedication to quality, precision, and client satisfaction. With years of industry experience, Vision Turning Component has established a reputation for providing high-quality products that fulfill the unique needs of its clients in a variety of sectors.

Commitment to Quality

Quality is more than an objective for Vision Turning Component; it is a basic value. The company follows the highest industry standards, including ISO 9001 certification, to ensure that all components meet or exceed client expectations. Vision Turning Components’ state-of-the-art quality control lab is outfitted with cutting-edge measurement and testing equipment, allowing the team to conduct thorough inspections at every stage of manufacturing.

Advanced Manufacturing Capabilities

Vision Turning Component has a wide selection of innovative manufacturing equipment, such as CNC machining centers, turning machines, and grinding machines. This equipment, along with the experience of highly qualified machinists and engineers, enables the organization to make components with unparalleled precision and consistency. Vision Turning Component can handle large-scale production runs as well as unique prototypes.

Diverse Industry Applications

Vision Turning Component provides machined components for a wide range of sectors, including automotive, aerospace, electronics, and medical equipment. The company’s extensive product line includes shafts, gears, bearings, fasteners, and custom components, all made to the exact specifications of its customers.

Global Reach and Reliable Supply Chain

With a global client base, Vision Turning Component recognizes the value of dependable supply chain management. Despite global supply chain problems, the company has created excellent partnerships with material suppliers and logistics partners to assure timely delivery. Vision Turning Component’s strategic location and effective production techniques help it achieve tight schedules and deliver products on time.

Innovation and Continuous Improvement

Vision Turning Component is dedicated to remaining at the forefront of industry advances. To stay competitive in a constantly changing market, the company invests in new machinery, software, and training on a regular basis. Vision Turning Components’ culture of continual improvement fosters innovation and efficiency, allowing the company to provide cutting-edge solutions to its customers.

Why Choose Vision Turning Component?

Choosing the proper source for industrial machined components is a key decision that will have a big impact on your company’s performance. Here are some of the reasons Vision Turning Component stands out as a reliable partner.

- High Quality: Vision Turning Components’ commitment to quality guarantees that every component is built to the highest standards, resulting in reliable and long-lasting products.

- Advanced Technology: To remain competitive, the company invests in innovative manufacturing methods and regularly refreshes its equipment.

- Customized Solutions: Whether you require a standard part or a custom-designed component, Vision Turning Component has the flexibility and competence to suit your specific needs.

- Global Reach: With a strong supply chain and global logistical capabilities, Vision Turning Component can deliver items to clients all over the world on schedule and in excellent shape.

- Vision Turning Component is dedicated to sustainable production processes, which will help you lower your environmental footprint while keeping the highest quality standards.

- Proven Track Record: With years of industry experience and a good reputation, Vision Turning Component has a track record of providing excellence on every project.

Conclusion

The industrial machined components supply sector is an essential component of modern manufacturing, allowing for the creation of high-quality, precision-engineered parts for a wide range of applications. As the market evolves, suppliers such as Vision Turning Component are setting the standard with modern technology, a commitment to quality, and an emphasis on customisation and sustainability.

Whether you work in the automotive, aerospace, electronics, or any other industry that requires precision machined components, selecting the proper supplier is critical. Vision Turning Components’ knowledge, ingenuity, and commitment to customer satisfaction make it the best partner for all of your industrial machined component requirements. With Vision Turning Component, you can be confident that you are receiving high-quality items that are suited to your unique needs and delivered with dependability and efficiency.