Fasteners Manufacturer in USA

Table of Contents

Introduction

Vision Turning Component – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned components Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality.

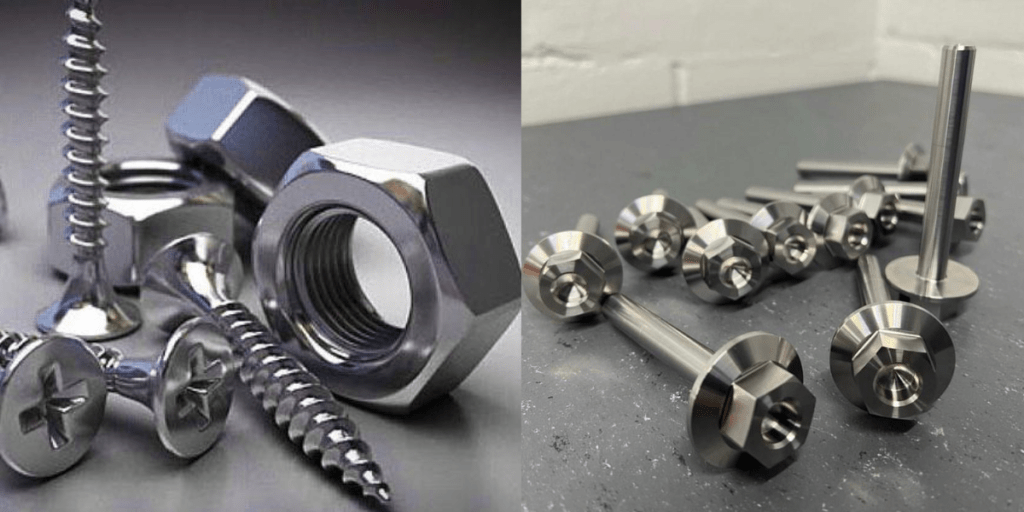

Fasteners are omnipresent, even if you may not give them much thought. Little things like your smartphone, the skyscraper straining for the sky, the chair you’re sitting on, and the car you drive hold our world together. Furthermore, fasteners made in the USA remain a top option in terms of quality, dependability, and innovation.Despite your lack of awareness, fasteners are everywhere. Our world is held together by small things like your smartphone, the building that is striving for the stars, the chair you are sitting on, and the vehicle you drive. Furthermore, when it comes to quality, reliability, and innovation, American-made fasteners continue to be a top choice. We are the best Fasteners Supplier in USA.

Why Choose Vision Turning Component

At Vision Turning Component, we consider the proper fastener to be a foundation rather than merely a component. We are dedicated to providing products that are more dependable, long-lasting, and perform better than expected. For your fastening needs, working with us makes sense for the following reasons: We are the best Fasteners Exporter in USA.

- Unwavering Dedication to Quality: At the core of all we do is quality. We make sure that every fastener we manufacture satisfies strict national and international standards by implementing strict quality control procedures throughout the manufacturing process. High tensile strength, remarkable corrosion resistance, and dimensional accuracy are ensured by our knowledgeable staff, cutting-edge equipment, and sophisticated inspection systems (such as optical inspection and sorting machines). In even the most demanding applications, we are committed to offering fasteners that are made to last and function flawlessly.

- Knowledge of a Wide Variety of Materials: To satisfy the particular needs of your project, we deal with a wide variety of materials. Premium brass, copper, aluminum, steel, stainless steel, mild steel (MS), bronze, and any other unique material composition you would need are all included in this. Your fasteners will last a long time and operate at their best thanks to our material selection process.

- At Our Heart: We recognize that off-the-shelf solutions aren’t always sufficient. When it comes to offering personalized fastening solutions, Vision Turning Component is exceptional. From initial design consultation and prototype development to final production, our skilled engineers work closely with you. In order to guarantee that your bespoke fasteners are precisely engineered, fulfilling the strictest tolerances and particular design demands, we make use of sophisticated machining techniques. This makes it possible to integrate your systems or goods with ease.

- Advanced manufacture Capabilities: We have state-of-the-art equipment and technology in our facilities to ensure accurate and efficient manufacture. This covers meticulous quality assurance procedures, CNC machining, and precise turning. Our technological investment enables us to consistently and accurately create complicated geometry.

- Competitive Pricing and Value: We think that excellent quality shouldn’t be prohibitively expensive. We provide competitive pricing without sacrificing the quality and integrity of our products by using cost-effective tactics and streamlined production procedures. Our objective is to offer affordable fastening solutions that improve your bottom line and create long-term value.

- Dependability and On-Time Delivery: On-time delivery is essential in the fast-paced production world of today. We promise to complete all orders quickly without sacrificing quality, so you can be sure you’ll have your components when you need them. Strict project deadlines are met by our effective production procedures.

- Going Beyond Fasteners All-inclusive Component Production: Although a large portion of our knowledge is in fasteners, Vision Turning Component is also a specialist in a variety of other premium industrial components, such as.

Applications of Fasteners

- Custom Fastener Components: A lot of specialty fasteners need customized shanks, specially made heads, or internal components that need to be turned precisely. These essential sub-components can be produced by Vision Turning Component to precise requirements, allowing fastener manufacturers to design custom solutions for difficult applications. For instance, Vision Turning Component can provide a custom-machined collar or a perfectly turned threaded insert that may be needed for a specific aerospace fastener.

- Precision Shafts and Pins: Vision Turning Component is an expert in creating high-precision shafts and pins that are utilized in a wide range of mechanical assemblies, in addition to conventional fasteners. These could be parts of the equipment that makes fasteners or they could be essential parts of the final goods that require fasteners (e.g., medical devices, optical equipment).

- Connections and Fittings: Properly fitting connections and fittings are essential to the integrity of many systems. The turning capabilities of Vision Turning Component are perfect for producing extremely precise and dependable parts for electrical, pneumatic, and hydraulic connections—all of which frequently depend on exact attachment techniques.

- Instrumentation and Sensor Components: Precisely turned parts are frequently used in devices that need to operate with great accuracy and consistency. This comprises parts for scientific instruments, sensors, and gauges where even the slightest variation can affect performance. Specialized tiny fasteners are frequently used by these equipment themselves.

- Bushings and Spacers: Accurately turned bushings and spacers are crucial for exact alignment and spacing in assemblies. These essential components can be produced by Vision Turning Component with the necessary surface polish and concentricity.

- Parts of Machinery Used in the Manufacturing of Fasteners: It’s a connection that cycles! Precision-turned parts are frequently necessary for the very machinery that manufacture premium fasteners to function. Vision Turning Component may improve the accuracy and efficiency of fastener production lines by supplying spindles and specialized tooling

Table of Specifications Fasteners

| Product Type | Size Range | Material | Thread Type | Coating/Finish | Standard |

|---|---|---|---|---|---|

| Hex Bolts | M3 to M56 | SS, MS, Brass | Metric, UNC, UNF | Zinc Plated, Hot Dip Galvanized | ASTM, ISO |

| Carriage Bolts | M4 to M36 | SS, MS | Metric | Self-Colored, Black Oxide | DIN, ASTM |

| U-Bolts | M6 to M42 | SS, MS | Metric | HDG, Electro-Plated | ISO |

| Hex Nuts | M3 to M56 | SS, MS, Brass | Metric, UNC | Plain, Nickel Plated | ASTM |

| Wing Nuts | M4 to M24 | SS, Brass | Metric | Zinc Plated | ISO |

| Flat Washers | M3 to M56 | SS, MS | NA | Plain, HDG | DIN |

| Spring Washers | M3 to M56 | SS, MS | NA | Self-Colored | DIN |

| Machine Screws | M2 to M16 | SS, Brass | Metric, UNC | Zinc Plated | ISO |

| Self-Tapping Screws | M2 to M10 | SS, MS | Metric | Self-Colored | ASTM |

| Blind Rivets | 2.4mm to 6.4mm | Aluminum, SS | NA | Anodized | ISO |

Advantage of Fasteners

- Supply Chain Security and Stability: The vulnerabilities of extensive international supply chains have been brought to light by recent world events. Businesses can save lead times, lower transportation risks and expenses, and improve inventory control by purchasing fasteners domestically in the USA. By fostering stronger supply chains, this local link lessens the impact of unanticipated disruptions.

- Faster Turnaround Times and Flexibility: Being close to a domestic manufacturer frequently results in more flexible production schedules, faster prototyping, and quicker answers to questions. This enables companies to quickly adjust to changes in the market and is particularly important for custom orders or unforeseen requests.

- nnovation and Customization: By investing in cutting-edge materials and technology, American fastener producers are frequently at the forefront of innovation. Additionally, they are quite good at creating custom fasteners that meet project specifications by providing unique sizes, materials, finishes, or patterns that are just not possible with off-the-shelf alternatives. Optimized solutions are made possible by this cooperative approach.

- Decreased Environmental Impact: Since local manufacturing requires fewer transportation miles, it typically results in a lower carbon impact. This is in line with customer desire for more sustainable practices and the expansion of corporate responsibility programs.

- Improved Communication and Cooperation: Having a domestic partner makes it simpler to communicate, removes language obstacles, and facilitates direct collaboration and on-site visits, all of which contribute to a more fruitful partnership.

- Support for the American Economy: Selecting a US manufacturer has a direct impact on economic expansion, job creation, and the development of the country’s manufacturing industry.

- Unwavering Quality Standards: American fastener producers follow accepted industry standards such as SAE (Society of Automotive Engineers) and ASTM (American Society for Testing and Materials) and are subject to strict quality control laws. Consistent material quality, accurate dimensions, and dependable performance are guaranteed by these requirements. This dedication to quality results in final goods that are safer, more resilient, and perform better.

Types of Fasteners

Bolts

Bolts are one of the most common types of fasteners. They are used in conjunction with nuts to hold materials together.

Types of Bolts:

- Hex Bolts

- Carriage Bolts

- Eye Bolts

- Anchor Bolts

- U-Bolts

Nuts

Nuts are used with bolts to secure the joint tightly. We offer a wide range of nut options.

Types of Nuts:

- Hex Nuts

- Lock Nuts

- Wing Nuts

- Cap Nuts

- Flange Nuts

Screws

Screws are versatile fasteners that can be used on their own or with nuts.

Types of Screws:

- Wood Screws

- Machine Screws

- Self-Tapping Screws

- Sheet Metal Screws

- Socket Head Screws

Washers

Washers are thin plates with a hole, typically used to distribute the load of a threaded fastener like a bolt or nut.

Types of Washers:

- Plain Washers

- Spring Washers

- Lock Washers

- Fender Washers

Conclusion

Innovation, the need for improved performance, and a rising focus on sustainability are driving change in the fastener industry. Any project’s success depends on selecting the best fasteners manufacturer in the USA or a worldwide partner who shares your dedication to accuracy and quality. At Vision Turning Component, we provide turned components that serve as the cornerstone of outstanding fastening solutions by fusing our vast knowledge, cutting-edge manufacturing capabilities, and constant commitment to client satisfaction.

We welcome you to discover the Vision Turning Component distinction, regardless of your industry—automotive, aerospace, medical, or any other that needs precision components. Allow us to be your dependable partner in creating a future that is supported by accuracy, strength, and dependability. We are the best Best Fasteners Manufacturer in USA.