Electrical Components Manufacturer in USA

Introduction

Vision Turning Component – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned components Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality.

As our world becomes more interconnected, electrical components serve as the unacknowledged workhorses that enable nearly all modern conveniences and technological progress. Whether in the smartphones we carry around or in the sophisticated devices behind industrial automation, these small but powerful components are essential to innovation. Regarding quality, reliability, and state-of-the-art technology, Electrical Component Manufacturers in the USA are leaders in innovation and the establishment of strong supply chains.For a long time, the U.S. has been a center of outstanding engineering and manufacturing strength. This legacy remains robust in the electrical components sector, where American firms are globally acknowledged for their dedication to precision, innovation, and rigorous quality control. We are the best Electrical Components Supplier.

Why is Electrical Components

Electrical components are the basic building blocks used in electrical circuits and systems. They are essential for controlling, modifying, and converting electric currents and voltages. These components ensure that electronic devices operate safely and efficiently. We are the best Electrical Components Exporter.

Why Choose Vision Turning Component

- Precision Engineering at Scale: Our approach merges the advantages of mass manufacturing with a steadfast commitment to precision. Our advanced facilities utilize cutting-edge CNC machining technology, enabling us to manufacture detailed electrical components with unparalleled precision and consistency, even for the most intricate geometries. We can achieve tolerances as tight as 0.0001 inches, guaranteeing perfect integration into your products.

- Diverse Material Adaptability: Regardless of whether your application demands copper’s remarkable conductivity, stainless steel’s robustness, aluminum’s lightweight nature, or brass’s particular traits, we possess the know-how and resources to handle a wide variety of materials.

- Extensive Product Portfolio: Vision Turning Component focuses on a diverse selection of electrical components, such as terminals, connectors, switches, and custom-machined parts essential for different electrical applications. We have expertise in components utilized in the automotive industry, industrial machinery, and other high-demand sectors.

- Quality Assurance without Compromise: Our dedication to quality is of the utmost importance. We apply strict quality control practices at every stage of the manufacturing process, starting with the sourcing of raw materials and concluding with the final inspection. We utilize sophisticated quality assurance tools, such as Video Measuring Machines (VMM) and Surface Roughness Testers, to guarantee that every component that departs from our facility complies with the most stringent industry standards.

- Production and Efficiency at an Accelerated Pace: Thanks to our state-of-the-art automation and optimized production methods, we can provide large quantities of components in a much shorter time frame. This efficiency results in a quicker time-to-market for your products, providing you with a competitive advantage.

- Customization and OEM Expertise: We recognize that each project has distinct requirements. Vision Turning Component specializes in tailored solutions and OEM manufacturing services, collaborating closely with clients to achieve their specific design, quantity, and budget objectives.

- Worldwide Presence with Emphasis on US Quality: Although we operate globally and cater to clients across the globe, our commitment to providing top-notch electrical components for the US market remains steadfast. We draw on our vast experience to satisfy the rigorous requirements of American industries.

- Devoted Customer Support: Our skilled professionals are dedicated to delivering outstanding customer service and technical assistance, guaranteeing a smooth experience from the first idea to the final delivery.

Application of Electrical Components

- Unmatched Precision: Thanks to our cutting-edge CNC machining, we can achieve extremely tight tolerances and uniform quality—essential for the dependable functioning of electrical components, as even slight variations can result in failure.

- Material Versatility: Our work encompasses a wide range of materials vital to the electrical industry. Thanks to this flexibility, we can fulfill varied demands for conductivity, insulation, and durability.

- Customization for Complex Needs: We recognize that standard solutions seldom meet the requirements of innovative electrical designs. To create tailored turned parts that exactly fit their individual requirements, our engineering team works in close partnership with clients.

- Scalable Production: Vision Turning Component provides adaptable manufacturing solutions that meet your changing requirements, from prototyping to large-scale production, guaranteeing a consistent supply of essential components.

- Global Reach, Local Impact: Although we operate on an international scale, our dedication to quality and effective logistics allows US manufacturers to utilize our capabilities to improve their supply chain while maintaining performance and reliability standards. We grasp the requirements of the worldwide market and excel at enabling seamless international collaborations.

- Dedication to Quality Control: Vision Turning Component follows strict quality control procedures at each step of the manufacturing process, just like top US manufacturers, guaranteeing that every component produced in our facility complies with the highest global standards.

- Automotive Electronics: The fast-growing electric vehicle (EV) market and the rising complexity of in-car electronics necessitate a large quantity of precision electrical components, including battery connectors, sensor housings, and control unit enclosures. The Vision Turning Component can provide high-quality, dependable components in large quantities, which makes it a partner of great worth.

- Medical Devices: The medical sector depends on highly accurate and dependable electrical components for a wide range of products, including diagnostic tools and surgical instruments. Vision Turning Component’s strict quality control guarantees that components conform to the demanding standards of this delicate industry.

- Consumer Electronics: Although consumer electronics usually consist of smaller components, their massive production creates a considerable market for precision-turned parts utilized in connectors, switches, and internal mechanisms.

Specification Table of Electrical Components

| Product Name | Material | Finish Type | Size Range | Application | Operating Temp. | Certifications |

|---|---|---|---|---|---|---|

| Brass Electrical Connectors | Brass CZ121 / C360 | Natural / Nickel Plated | M2 to M24 | Automotive, Control Panels | -10°C to +80°C | RoHS, CE |

| Terminal Blocks | Polycarbonate / Nylon | Flame Retardant Coating | 1A to 100A | Electrical Distribution Systems | -20°C to +100°C | UL, CE |

| Busbars | Copper / Aluminium | Tin / Silver Plated | 5mm to 30mm width | Power Distribution Panels | -30°C to +125°C | RoHS |

| Electrical Relays | Brass / Copper Contacts | Silver Coated | 5A to 40A | Industrial Machinery, Automation | -20°C to +85°C | CE, ISO 9001 |

| Fuse Holders | Brass / ABS | Natural / Black | 5mm, 6mm, 10mm | Circuit Protection | -10°C to +60°C | UL |

| Custom CNC Electrical Parts | Brass / SS / Aluminium | As Per Requirement | Customized | OEM Assemblies | As Per Requirement | RoHS, ISO 9001 |

Types of Electrical Components

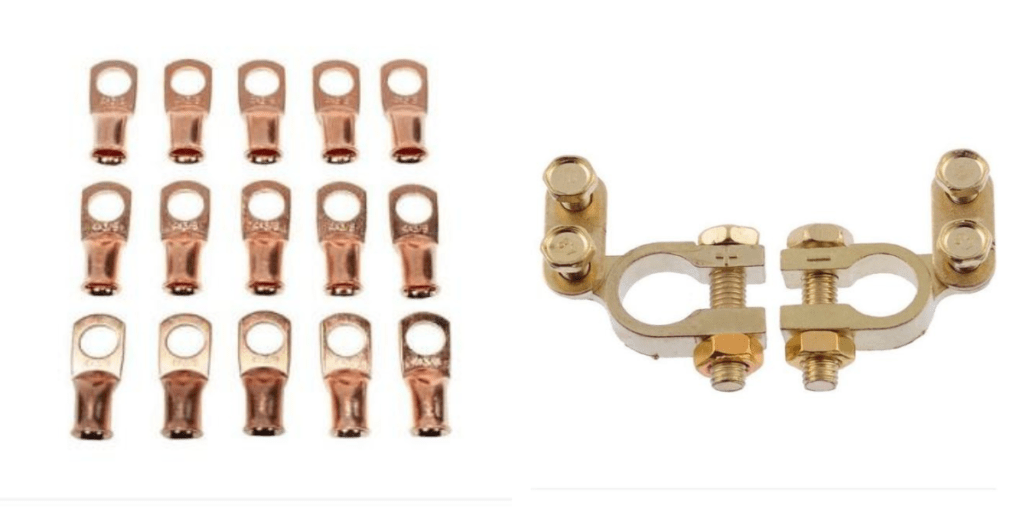

Connectors and Terminals

- From heavy-duty industrial connectors to compact automotive terminals, Vision Turning Component offers reliable connection solutions that ensure secure and efficient electrical pathways.

Switches

- Available in various forms like toggle switches, push-button switches, and rotary switches, these components are built for precision control in demanding environments.

Precision Turned Electrical Parts

- As specialists in precision turning, the company manufactures custom-designed turned electrical components such as contact pins, socket components, and electrical fittings made from high-grade brass, copper, aluminum, and stainless steel.

Cable Glands and Accessories

- Designed for cable management and protection, Vision Turning Component’s cable glands are available in multiple sizes, materials, and configurations.

Brass Electrical Components

- Including brass inserts, electrical plugs, sockets, pins, and terminal blocks — known for their superior conductivity and corrosion resistance.

Industrial Fittings and Connectors

- Specialized fittings for electrical enclosures, control panels, and industrial systems, built to withstand harsh operating conditions.

Custom Electrical Assemblies

- The company provides assembly services for custom electrical and electronic products, combining multiple components into ready-to-use assemblies.

Conclusion

The landscape of electrical component manufacturing in the USA is experiencing a significant resurgence, driven by a renewed emphasis on quality, supply chain resilience, intellectual property protection, and technological innovation. While challenges persist, the advantages of domestic production are increasingly clear, fostering a more secure and efficient manufacturing ecosystem. We are the best Best Electrical Components Manufacturer.

In this dynamic environment, collaboration and strategic partnerships are key. As U.S. manufacturers continue to push the boundaries of electrical component design and production, they can benefit immensely from reliable partners who specialize in precision components. Vision Turning Component, with its unwavering commitment to quality, advanced manufacturing capabilities, and comprehensive service offerings, stands ready to support electrical component manufacturers, both domestically and internationally, in achieving their goals and contributing to the continued growth and innovation of this vital industry. The future of electrical component manufacturing in the USA is bright, built on a foundation of precision, resilience, and strategic collaboration.