CNC Components Supplier in Jamnagar

Table of Contents

Introduction

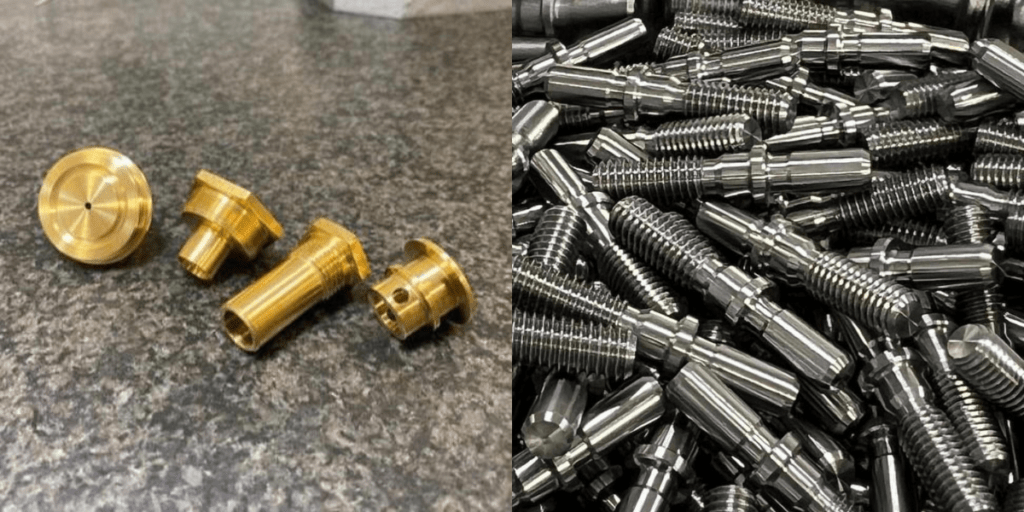

Vision Turning Component – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned components Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality.

Known as the “Brass City” of India, Jamnagar has long been a manufacturing powerhouse, especially in the field of precision metal components. The city has become a center for suppliers of CNC components as a result of its embracing of the technology revolution in recent decades. A new era of accuracy, productivity, and sophisticated manufacturing capabilities has been ushered in by this evolution, making Jamnagar an essential location for businesses looking for premium parts. We are the best CNC Components Manufacturer.

We’ll go into great detail about the world of CNC components in Jamnagar in this extensive guide, including why this city is a great place to source, what sorts of components are easily accessible, and—most importantly—how to find a trustworthy partner for your requirements. And Vision Turning Component is the name that sticks out when it comes to dependability and quality.

The Rise of CNC Components

Jamnagar’s transformation from a traditional brass manufacturing center to a state-of-the-art CNC hub is evidence of its adaptability and spirit of entrepreneurship. The city has long been known for producing exquisite brass parts due to its wealth of brass resources and talented artisans. However, the use of Computer Numerical Control (CNC) technology became not only advantageous but also essential as needs throughout the world changed toward more precision, intricate designs, and quicker production cycles. We are the best CNC Components Exporter.

Why Choose Vision Turning Component

- Unwavering Commitment to Precision: Our name, “Vision Turning Component,” isn’t just a name – it’s our promise. We live and breathe precision. Our state-of-the-art CNC turning and machining centers are meticulously maintained and operated by highly skilled technicians who are masters of their craft. We consistently achieve exceptionally tight tolerances, ensuring every part we deliver meets your exact specifications, every single time.

- Cutting-Edge Technology & Infrastructure: We invest heavily in the latest CNC machinery and advanced software. This ensures we can handle the most complex geometries, work with a wide range of materials (including brass, stainless steel, aluminum, and more), and deliver superior surface finishes. Our robust infrastructure is geared for both prototyping and high-volume production.

- Rigorous Quality Control: Quality isn’t an afterthought at Vision Turning Component; it’s integrated into every stage of our process. From raw material inspection to in-process checks and final verification using advanced metrology equipment, we adhere to stringent quality management protocols. Our commitment to quality ensures zero defects and consistent performance.

- Extensive Experience and Expertise: With years of experience serving diverse industries, we have developed a deep understanding of various application requirements. Our expert team can provide valuable insights and design-for-manufacturability (DFM) feedback, optimizing your designs for cost-effectiveness and performance.

- Customer-Centric Approach: We believe in building lasting partnerships, not just making transactions. Our communication is clear, prompt, and transparent. We work closely with our clients, understanding their unique needs and providing tailored solutions. Your satisfaction is our driving force.

- Timely Delivery: We understand the critical importance of deadlines in your supply chain. Our efficient production processes and meticulous planning ensure that your orders are delivered on time, every time, helping you maintain your production schedules without interruption.

- Competitive Value: While we never compromise on quality or precision, we strive to offer competitive pricing. Our streamlined operations and efficient use of resources translate into cost-effective solutions for our clients, providing excellent value for your investment.

- Versatility in Materials and Applications: Whether you require components for electrical fittings, automotive parts, industrial machinery, or specialized custom applications, our expertise spans a wide spectrum of materials and designs. We are adept at handling intricate components in various grades of brass, stainless steel, and aluminum.

Applications of CNC Components

- Automotive Industry: From intricate engine parts and braking system components to specialized fasteners and connectors, our CNC turned parts are crucial for the performance, safety, and reliability of vehicles. We manufacture components for both conventional and electric vehicles, contributing to the evolving automotive landscape.

- Electrical and Electronics Industry: The demand for miniature, high-precision components is immense in the electrical and electronics sector. We produce connectors, terminals, pins, switch parts, and various intricate components for switchgear, sensors, circuit boards, and other electronic devices, ensuring optimal electrical conductivity and durability.

- Hydraulics and Pneumatics: Precision is paramount in hydraulic and pneumatic systems where fluid and air pressure are controlled. We manufacture critical components like fittings, valves, nozzles, adaptors, and shafts that demand exceptional dimensional accuracy and surface finish to prevent leaks and ensure efficient operation.

- Medical Devices: The medical industry requires components with the highest levels of precision, biocompatibility, and reliability. We produce parts for surgical instruments, diagnostic equipment, dental tools, and various medical devices, adhering to stringent quality and cleanliness standards.

- Aerospace and Defense: In industries where failure is not an option, our CNC components provide the reliability and strength required. We manufacture precision parts for aircraft systems, defense equipment, and other demanding applications where extreme accuracy and robust materials are essential.

- Industrial Machinery and Equipment: From heavy machinery to specialized industrial tools, our components form the backbone of numerous industrial applications. This includes shafts, gears, bushings, couplings, and other critical parts that ensure the smooth and efficient operation of manufacturing lines, automation systems, and various industrial equipment.

- Construction and Plumbing: Our components are integral to modern construction and plumbing systems. We produce durable and corrosion-resistant parts like pipe fittings, valve components, and specialized connectors that can withstand harsh environments and ensure long-term performance.

- Consumer Goods: Even in everyday products, precision CNC components play a vital role. We contribute to the manufacturing of parts for appliances, consumer electronics, and various other goods where accuracy and aesthetic finish are important.

Table of Specifications CNC Components

| Parameter | Specification |

|---|---|

| Material | CNC Components |

| Size Range | 2 mm to 100 mm Diameter (Custom Available) |

| Tolerance | Up to ± 0.01 mm |

| Surface Finish | Polished, Nickel Plated, Chrome Plated, Natural |

| Thread Type | Metric, BSP, UNF, NPT, Custom |

| Standard Followed | DIN, ISO, JIS, ANSI, IS |

| Production Capacity | 1,00,000+ Pieces per Month |

| Packaging | Export Quality, Eco-friendly, Custom Labeling |

| Delivery | Domestic & Export (Lead Time 5-15 Days) |

Benefits of CNC Components

- Reduced Total Cost of Ownership: VTC’s precision manufacturing reduces the likelihood of defects and rework, leading to significant cost savings in the long run. Their competitive pricing, combined with high-quality, durable components, translates to a lower overall cost of ownership for your projects.

- Enhanced Product Performance: The superior precision and quality of VTC’s components directly contribute to the enhanced performance and reliability of your final products. This is particularly crucial in high-stakes industries like aerospace and medical.

- Streamlined Supply Chain: By partnering with a reliable and efficient supplier like VTC in Jamnagar, you can streamline your supply chain, reduce logistical complexities, and improve overall operational efficiency.

- Innovation and Technical Support: VTC’s team of experts is not just about manufacturing; they are also a resource for innovation. They can offer valuable insights and technical support during the design and development phases, helping you optimize your components for manufacturability and performance.

- Sustainable Practices: VTC understands the importance of sustainable manufacturing. While specific details might vary, many manufacturers in Jamnagar, especially in the brass industry, are known for incorporating recycled materials and eco-friendly practices, contributing to a greener future.

- Timely Delivery: We understand the importance of project deadlines. Our streamlined production processes, efficient planning, and robust logistics ensure that your orders are delivered on time, every time, helping you maintain your production schedules.

- Competitive Edge: While we prioritize quality and precision, we also understand the need for cost-effectiveness. Our optimized processes and efficient resource utilization allow us to offer competitive pricing without ever compromising on the superior quality you deserve.

Types of CNC Components

1. CNC Turned Components

- These are parts produced by rotating the raw material and cutting it with precision tools. Turned components are used in industries like automotive, hydraulic, and electrical. Vision Turning Component offers:

- Brass turned parts

- Stainless steel turned parts

- Aluminum turned parts

- Copper turned parts

2. CNC Milled Components

- Milling components involves cutting and drilling materials to achieve the required design. Our milled parts offer high surface finish and tight tolerances. Ideal for:

- Aerospace fittings

- Machinery housings

- Automotive engine parts

3. Custom CNC Components

- If you need parts made as per your unique design or drawing, Vision Turning Component provides complete custom CNC machining solutions. We offer prototyping to final production, ensuring your specifications are met.

4. Threaded Components

- These components include:

- Nuts, bolts, and studs

- Precision threads in various standards (metric, BSP, NPT)

- Internal and external threading

We ensure the threading is precise and compatible with international fitting requirements.

5. Electrical & Electronic CNC Components

- We also manufacture precision components for the electrical and electronics industries such as:

- Terminal blocks

- Brass connectors

- PCB terminals

- Cable glands

6. Automotive CNC Parts

- From engine components to brake systems, we supply high-quality parts for:

- Two-wheelers and four-wheelers

- Agricultural vehicles

- Heavy-duty machinery

Conclusion

The industrial environment of Jamnagar is vibrant and still uses cutting-edge production techniques. Businesses aiming for accuracy, productivity, and worldwide competitiveness must have high-quality CNC components; this is not merely a fad. We are the best Best CNC Components Supplier.

Selecting the best provider of CNC components is a crucial choice. It affects manufacturing schedules, product quality, and, eventually, profitability. Working with a local specialist like Vision Turning Component gives you access to cutting-edge facilities, a highly qualified staff, a wide selection of products, and an uncompromising dedication to quality—all of which are provided with the ease and promptness of a local partner.