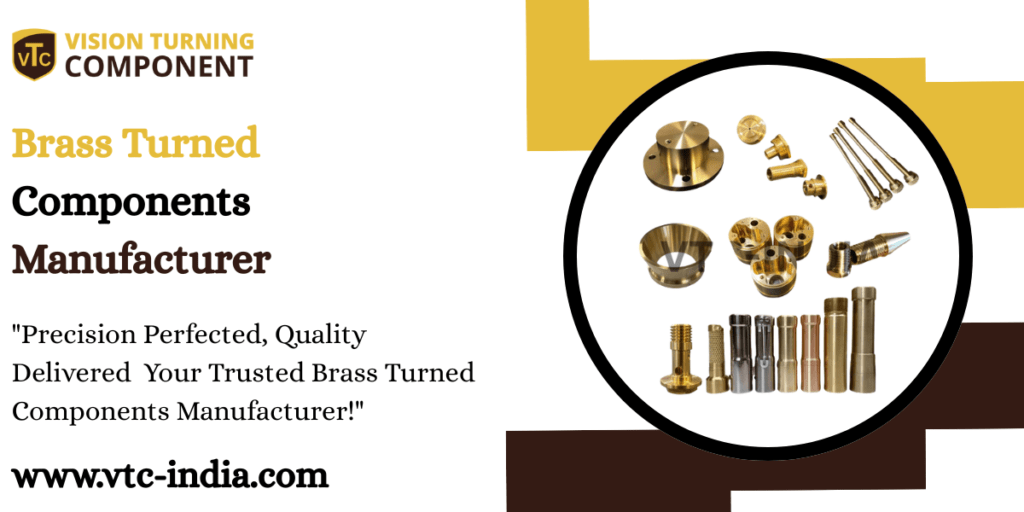

Brass Turned Components Manufacturer

Table of Contents

Introduction

Vision Turning Component – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned components Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality.

The complex realm of manufacturing comprises innumerable tiny components that are essential to the overall system. Brass turned components are particularly noteworthy as essential workhorses, diligently carrying out their tasks in a remarkable variety of industries. These small components, whether found in the precise mechanisms of a top-tier camera or the durable fittings of a plumbing system, are essential to the performance and dependability of a multitude of items we use daily.

As a designer, engineer, or procurement specialist, it is essential to grasp the realm of brass turned components and how to select the appropriate manufacturer. In this article, these crucial components will be clarified, their extensive uses examined, and a company devoted to quality and precision—Vision Turning Component—will be presented. We are the best Brass Turned Components Supplier.

What Exactly Are Brass Turned Components

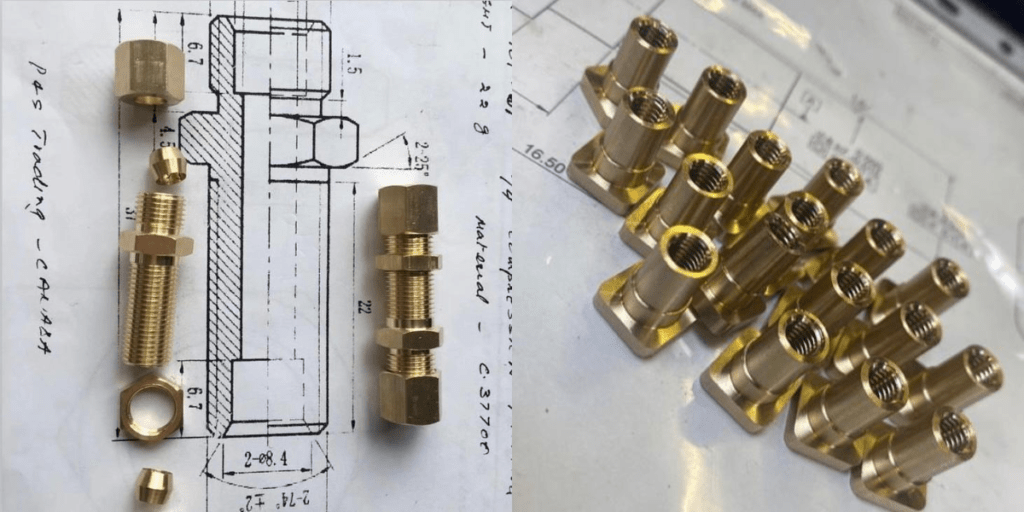

Envision a solid brass rod. Picture a highly accurate device that can rotate this rod rapidly while a sharp cutting implement gradually removes material to form a precise shape. The procedure is referred to as “turning,” and the resulting parts are known as “turned components.” A brass turned component is a precisely machined part, typically cylindrical or symmetrical, made from a solid brass rod or bar using a lathe or turning machine. Consider screws, nuts, bolts, shafts, pins, connectors, valves, and countless custom parts – many of these can be made as brass turned components. We are the best Brass Turned Components Exporter.

Why Choose Vision Turning Component

- Precision Engineering: For us, quality is more than a buzzword; everything we do is built on it. Utilizing cutting-edge CNC turning centers and other sophisticated machinery, we accomplish remarkably tight tolerances and uniform quality on each individual component. The components we provide comply with industry standards and are often of superior quality.

- Rigorous Quality Control: Stringent quality control measures are applied at each step of the production process, starting with raw material examination and culminating in final product validation. Our devoted quality assurance team employs exact measuring tools (like CMMs, calipers, micrometers, and profile projectors) to guarantee dimensional accuracy, surface finish, and functional integrity.

- Material Excellence: We procure brass alloys of the highest grade from reliable suppliers. We guarantee that the material perfectly fits your needs, whether you require free-machining brass for standard applications, lead-free brass to comply with environmental regulations, or a specific alloy with enhanced properties.

- Modern Machinery Fleet: Our manufacturing facility features a wide variety of state-of-the-art turning machines, such as multi-axis CNC lathes and sophisticated secondary operation equipment. We can manage both high-volume production and complex, detailed components with the same level of efficiency and accuracy.

- Skilled Workforce: Our team consists of seasoned engineers, machinists, and quality control experts with extensive knowledge in brass turning. It is their expertise and scrupulous regard for detail that makes the conversion of basic materials into precision components possible.

- Customization is Essential: We recognize that ready-made solutions seldom provide a perfect fit. Vision Turning Component focuses on producing custom brass turned components that meet your precise drawings, specifications, and performance needs. From the initial concept to the final completion, we collaborate closely with our clients.

- Diverse Selection: We manufacture a wide variety of brass turned components, ranging from basic pins and bushes to intricate multi-featured connectors and specialized fittings, suitable for different applications in multiple industries.

Applications of Brass Turned Components

Electrical & Electronics Industry

- Brass terminals, connectors, and neutral links are widely used in control panels, switchboards, and electronic devices.

- Brass electrical plugs and sockets ensure safe and efficient power connections.

Automotive Industry

- Brass auto parts such as bushes, screws, and connectors are essential in fuel systems, braking mechanisms, and electrical wiring.

- They ensure high durability and corrosion resistance in vehicles.

Plumbing & Sanitary Fittings

- Brass pipe fittings, valves, and unions are used in plumbing installations due to their excellent resistance to corrosion and wear.

- Ideal for water, gas, and air applications in residential and commercial buildings.

Gas Fittings & Control Systems

- Brass is preferred for gas regulators, nozzles, and valves because of its leak-proof properties and high tensile strength.

Telecommunication

- Used for cable glands, earthing accessories, and connectors in telecommunication towers and networks.

Aerospace & Defense

- Precision brass turned components are used in aerospace equipment and military applications where durability and reliability are crucial.

Specification Table of Brass Turned Components

| Specification | Details |

|---|---|

| Material | Brass Turned Components |

| Size Range | 2 mm to 50 mm (Diameter) and length as required |

| Tolerance | ± 0.02 mm (Customizable) |

| Threads | Metric, BSP, BSPT, NPT, UNC, UNF, BA, ISO, or as specified |

| Finish Available | Natural, Nickel Plated, Chrome Plated, Tin Plated, Gold Plated, Silver Plated |

| Standards | DIN, ISO, ASTM, BS, JIS or as per custom specifications |

| Packaging | Standard export packaging or as per customer requirement |

| Production Capacity | 10,00,000 pcs per month |

| Applications | Electrical, Automotive, Plumbing, Aerospace, Telecommunication, Instrumentation |

Types of Brass Turned Components

1. Brass Electrical Components

- These are vital parts used in electrical panels, control systems, and wiring applications. Common products include:

- Brass terminal blocks

- Brass plugs and sockets

- Electrical brass connectors

- Brass pins and contacts

2. Brass Automotive Components

- We manufacture precision brass components used in the automobile sector, including:

- Brass fuel line fittings

- Brass hose connectors

- Brass bushings

- Brass nuts and bolts

3. Brass Sanitary Components

- High corrosion resistance makes brass ideal for plumbing and sanitary fittings. Our products include:

- Brass valves

- Brass unions

- Pipe couplings

- Brass adapters

4. Brass Machine Turned Parts

- These are customized parts manufactured as per client drawings or samples:

- Precision turned parts

- Brass inserts

- Brass studs

- Threaded rods and spacers

5.Brass Telecommunication Components

- Used in communication equipment for safe and reliable connectivity:

- Brass cable glands

- Brass connectors

- RF connectors

- Cable assembly parts

Conclusion

In an environment where accuracy and dependability are essential, Vision Turning Component emerges as your reliable ally for superior brass turned components. Every component we manufacture reflects our quest for perfection, thanks to our commitment to advanced manufacturing methods, stringent quality control, extensive material knowledge, and steadfast dedication to customer satisfaction.For your next project that requires brass turned components which are precise, durable, and economical, opt for Vision Turning Component. We can assist you in making your visions real, with each perfectly crafted brass component bringing you closer. We are the best Best Brass Turned Components Manufacturer.