Brass Electrical Components Manufacturers in India

Introduction

Vision Turning Component – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned components Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality.

High-quality electrical components are essential to the efficient operation of machines, electronics, and other power systems in the fast-paced industrial world of today. Brass electrical components have gained a lot of popularity among these because of their superior conductivity, robustness, and corrosion resistance. One of the biggest production centers, India has become a leading source for high-quality brass electrical components.Businesses like Vision Turning Component stand out for their knowledge, excellence, and dedication to client pleasure if you’re looking for trustworthy manufacturers of brass electrical components in India. We are the best Brass Electrical Components Supplier.

Why Are Brass Electrical Components

Electrical components consisting of brass, a copper and zinc alloy, are widely utilized in electrical systems. They are essential for maintaining appropriate conductivity, robustness, and corrosion resistance. These elements can be found in. We are the best Brass Electrical Components Exporter.

Why Choose Vision Turning Components

- Uncompromising Commitment to Quality: For us, quality isn’t a department; it’s a culture. Every single brass component that leaves our facility undergoes a rigorous quality check. We adhere to international standards and employ state-of-the-art inspection tools to ensure that every pin, every terminal, and every connector meets the precise specifications and tolerances you require. When you choose Vision Turning Components, you choose peace of mind.

- State-of-the-Art Manufacturing Capabilities: We believe that quality output requires quality input. Our manufacturing unit is equipped with advanced CNC Computer Numerical Control machines and automated lathes. This technology allows us to produce high volumes of components with incredible accuracy, repeatability, and a flawless surface finish, batch after batch.

- A Culture of Precision Engineering: We are more than just manufacturers; we are solution providers. Our team of experienced engineers and technicians works closely with clients to understand their unique challenges. Whether you need a standard component or a custom-designed part for a specialized application, we have the expertise to turn your vision into a tangible, high-performing reality.

- Customer-Centric Approach: We understand that every client’s needs are unique. We pride ourselves on our responsive communication, flexible approach to orders both large and small and our commitment to on-time delivery. We see ourselves as an extension of your supply chain, dedicated to helping your business succeed.

- Competitive Pricing without Compromise: By optimizing our manufacturing processes and maintaining high operational efficiency, we are able to offer competitive pricing without ever cutting corners on the quality of our materials or our workmanship. We deliver true value for your investment.

- Advanced Manufacturing Capabilities: We believe that precision is achieved through the right blend of human skill and cutting-edge technology. Our manufacturing floor is equipped with modern CNC turning centers, automatic lathes, and secondary operation machines. This allows us to produce components with complex geometries, exceptional surface finishes, and tolerances that leave no room for error.

- Expertise in High-Volume Production: We understand the demands of the global market. Our production infrastructure is designed for scalability and efficiency, enabling us to handle large-volume orders without sacrificing quality or missing deadlines. You can rely on us to be a steady, dependable part of your supply chain.

- Customer-Centric Solution Engineering: We see ourselves as an extension of your team. Our engineering team works closely with clients to understand their unique challenges. Whether you need a standard component or a custom-designed part, we provide technical support and value engineering to optimize the design for performance, cost, and manufacturability.

- Consistent and Reliable Delivery: In today’s fast-paced world, timely delivery is critical. We have streamlined our logistics and supply chain processes to ensure that your orders reach you on time, every time. Our reliability helps you maintain your production schedules and keep your promises to your customers.

Applications of Brass Electrical Components

1. Electrical Panels and Switchboards

- Brass connectors, terminals, and fasteners are widely used in electrical panels and switchboards. They provide reliable conductivity and ensure stable connections in high-voltage circuits.

2. Consumer Electronics

- From home appliances to gadgets, brass pins and connectors are essential in consumer electronics, offering both durability and efficient conductivity.

3. Switches and Plugs

- Switches, plugs, and sockets require materials that can handle repeated use without degrading. Brass pins and contacts are ideal due to their durability and conductivity.

4. Automotive Industry

- Brass electrical components are extensively used in vehicles for wiring, battery terminals, and switches. Their resistance to corrosion ensures consistent performance in varying environmental conditions.

5. Consumer Electronics

- From home appliances to industrial machinery, brass components are used in switches, connectors, and circuit boards, providing safety and efficiency.

6. Telecommunication Systems

- Brass components are used in connectors, terminals, and plugs within telecommunication systems, ensuring clear and uninterrupted signal transmission.

7. Industrial Equipment

- Heavy machinery and industrial equipment use brass electrical components to maintain performance under high load and harsh conditions.

Table of Specifications Brass Electrical Components

| Component Type | Material | Finish | Conductivity | Size Range (mm) | Application |

|---|---|---|---|---|---|

| Brass Terminals | Brass Electrical Components | Nickel Plated | High | 1 – 20 | Automotive, Appliances |

| Electrical Connectors | C272 Brass | Tin Plated | Medium-High | 2 – 25 | Power Distribution, Panels |

| Brass Plugs | C360 Brass | Polished | High | 5 – 30 | Consumer Electronics |

| Switch Contacts | C268 Brass | Gold Plated | High | 1 – 15 | Industrial Machinery |

| Precision Components | C360 Brass | Machined | High | Custom Sizes | Automotive & Electrical Use |

Advantage of Brass Electrical Components

- Superior Electrical Conductivity: Brass is an excellent conductor of electricity. While not as conductive as pure copper, it offers a fantastic balance of performance and strength, ensuring minimal energy loss as heat at connection points.

- Incredible Machinability: This is brass’s superstar quality. It is softer and easier to machine than many other metals. This allows Brass Electrical Components Manufacturers in India to create complex, high-precision parts like terminals, connectors, and pins with smooth surfaces and tight tolerances. A smooth surface means better contact and less resistance.

- Natural Corrosion Resistance: Brass naturally resists rust and corrosion. This is vital for components that might be exposed to moisture, varying temperatures, or different atmospheric conditions, ensuring long-term reliability and safety.

- High Strength and Durability: Brass components are strong and resistant to wear and tear. They can withstand the physical stress of repeated connections and disconnections, making them ideal for plugs, sockets, and switches.

- Excellent Thermal Conductivity: Brass dissipates heat quickly. In electrical applications where heat buildup is a common cause of failure, this property helps keep temperatures down, protecting the component and the entire system.

- Self-Lubricating Properties: The zinc in brass gives it slight self-lubricating qualities. This is particularly useful in components like threaded connectors, making them easier to screw together and reducing galling or seizing.

- A Culture of Customization: Your design challenges are unique. We thrive on them. Our engineering team works closely with clients to understand their specific requirements. We specialize in customizing components to fit exact design specifications, offering expert advice on design for manufacturability (DFM) to optimize performance and cost.

- Cost-Effectiveness Without Compromise: By leveraging our engineering expertise and efficient production processes, we eliminate waste and optimize resource usage. This operational efficiency allows us to offer highly competitive pricing, giving you the dual benefit of superior quality and excellent value for your investment.

- Customer-Centric Partnership: At Vision Turning Components, you are a partner, not just a client. We pride ourselves on our transparent communication, responsive support, and collaborative approach. We keep you informed at every stage of the process, from initial quote to final delivery, building a relationship based on trust and mutual success.

Types of Brass Electrical Components

1. Brass Connectors

- Brass connectors are used to join electrical circuits safely and efficiently. They are reliable for power transmission and are commonly found in household wiring, industrial machinery, and automotive electrical systems.

2. Brass Terminals

- Brass terminals connect wires to electrical devices. Their corrosion resistance ensures a secure and long-lasting connection, reducing the risk of short circuits or energy loss.

3. Brass Bushings

- Brass bushings are used to reduce friction in electrical equipment, allowing smooth movement of parts. They are widely used in motors, generators, and transformers.

4. Brass Pins and Sockets

- These components are essential in plug and socket assemblies. Brass pins provide excellent conductivity and mechanical strength, ensuring stable electrical connections.

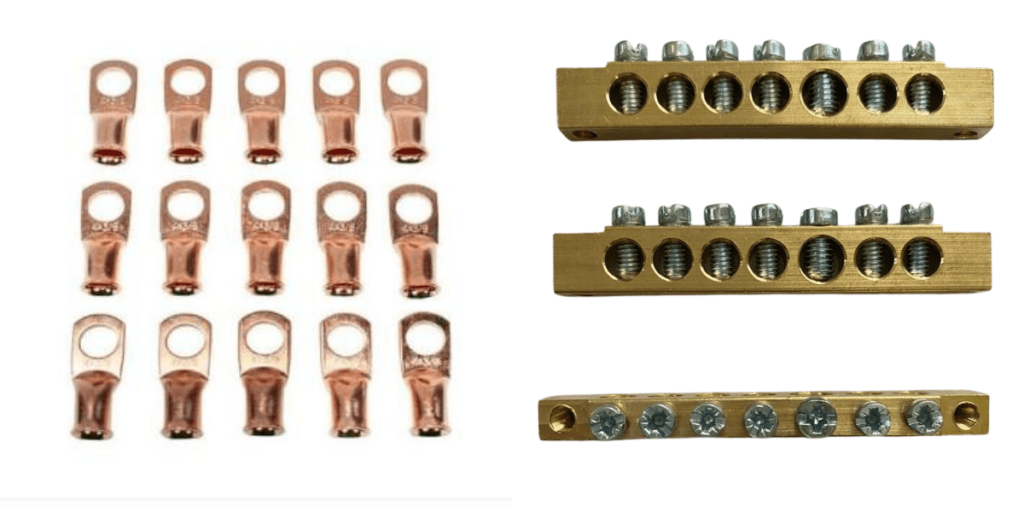

5. Brass Cable Lugs

- Brass lugs are used to connect electrical cables to equipment securely. Their robust construction prevents damage to the cables and ensures consistent electrical performance.

6. Custom Brass Components

- Manufacturers like Vision Turning Component also provide custom brass parts designed according to client specifications. This ensures compatibility with specialized electrical systems and industrial applications.

Conclusion

For electrical systems to be both safe and effective, brass components are necessary. India has established itself as a reliable supplier of premium brass components because to its highly qualified labor force and sophisticated manufacturing facilities. Vision Turning Component distinguishes out among the top producers due to its dependability, quality, and customer-focused philosophy. Vision Turning Component offers robust solutions that support industries throughout India and beyond, whether you require connectors, terminals, or customized brass parts. We are the Best Brass Electrical Components Manufacturer.

Working with a reputable manufacturer like Vision Turning Component allows businesses to concentrate on expansion and innovation by ensuring not only high-quality products but also peace of mind. Vision Turning Component is a reliable name for any business looking for the best brass electrical components in India.