Aluminium Turning Components Supplier

Introduction

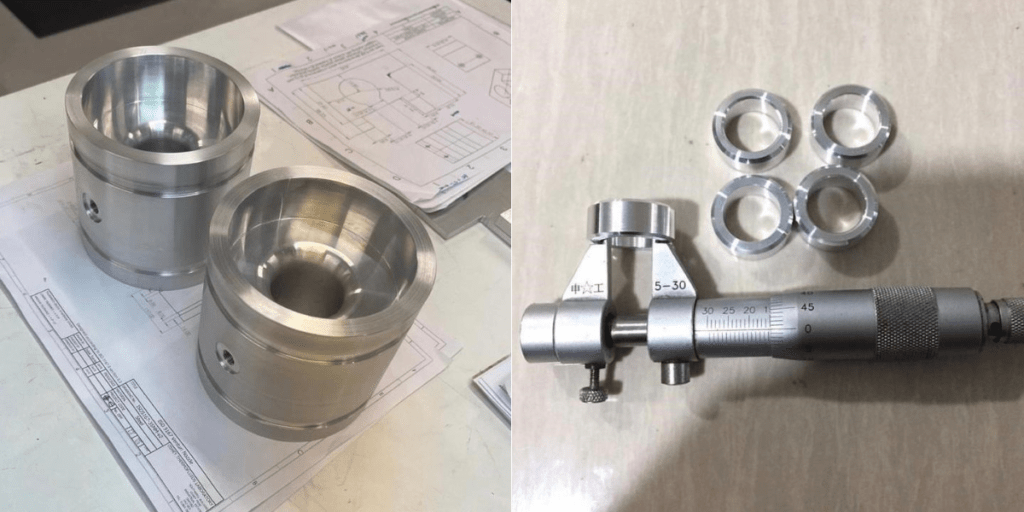

Vision Turning Component – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned components Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality.

In the contemporary manufacturing industry, which moves at a rapid pace, precision reigns supreme. Whether it’s a minuscule medical apparatus or a massive aerospace engine, each part is crucial. Aluminium turning components are remarkable yet underappreciated parts that are lightweight, durable, and versatile.You may be asking yourself what “aluminium turning components” actually are. In simple terms, these components are crafted from aluminium and have been shaped and machined through a method known as turning. Envision a high-velocity spinning aluminum block being meticulously shaped into the intended form by a specialized cutting tool. This process of turning makes it possible to create designs that are exceptionally detailed and accurate. We are the best Aluminium Turning Components Manufacturer.

What are Aluminium Turning Components

Picture a block or rod made of aluminium, rotating rapidly. Picture a specialized cutting instrument meticulously sculpting this rotating metal, excising minuscule fragments until it achieves the precise intended form. The method is referred to as turning, and the resulting parts are termed turned components. When this process is applied to aluminium, it results in aluminium turning components.

These parts are usually produced with sophisticated equipment such as CNC (Computer Numerical Control) lathes, which are operated by computer programs to guarantee remarkable precision and uniformity. We are the best Aluminium Turning Components Exporter.

Why Choose Vision Turning Component

- Unflinching Accuracy and Precision: Vision Turning Component places precision at the heart of all our activities. To guarantee that each part conforms to the most stringent tolerances and specifications, we employ cutting-edge CNC machinery and sophisticated turning methods. Each component is scrutinized with care by our expert technicians, who ensure that it meets the required dimensions and performs reliably.

- High-Quality Materials: Our conviction is that outstanding components begin with high-quality materials. We utilize only premium-grade aluminium, guaranteeing that our components are lightweight, exceptionally robust, and highly resistant to corrosion. Every part we supply is guaranteed to be reliable and durable, thanks to our commitment to quality materials.

- Tailored Answers for Your Requirements: We recognize that each industry and project has specific needs. From design consultation to prototype development and final production, our skilled team collaborates closely with you to deliver customized solutions that align perfectly with your unique needs. We have the capabilities to deliver, whether you need a small batch of prototypes or large-scale production.

- Excellence without Excessive Cost: A high standard can be affordable. We can provide economical solutions that maintain the high quality of our products, thanks to our efficient production techniques and competitive pricing. Our goal is to help you accomplish your project objectives while staying within budget by providing long-term value.

- Delivering on Time, Always: We understand that delays can throw off your production schedule. With our efficient procedures and committed logistics team, your components are reliably delivered on schedule, aiding you in sustaining uninterrupted operations.

- Certified: We are certified to demonstrate our commitment to quality, not just stating it. As an ISO 9001:2015 certified company, Vision Turning Component demonstrates its commitment to strict quality management systems and international standards.

Applications of Aluminium Turning Components

- Automotive Industry: Aluminium turning components, ranging from engine parts and transmission components to suspension elements and wheel hubs, play a vital role in creating vehicles that are lighter, more fuel-efficient, and higher-performing.

- Aerospace Sector: The lightweight property of aluminium is essential in this context. It is utilized in structural components of aircraft, engine parts, and interior fittings, having a direct effect on fuel economy and flight performance.

- Electronics: The superior thermal and electrical conductivity of aluminium makes it essential for heat sinks, connectors, casings, and various internal components in consumer electronics, computers, and telecommunications equipment.

- Medical Devices: Due to its precise nature and resistance to corrosion, aluminium is ideal for use in instruments, equipment housings, and even internal components of various medical devices.

- Construction: Structural elements, window frames, and decorative features are made from lightweight yet strong aluminum components, providing durability and visual appeal.

- Industrial Machinery: The precision and wear resistance of turned aluminium often benefit bearings, shafts, gears, and other moving parts in various industrial machines.

- Lightweight Champion: Aluminium’s weight is astonishingly low in comparison to that of steel. This provides a huge benefit for sectors where every gram is crucial, such as aerospace, automotive, and portable electronics. Components that weigh less translate to improved fuel efficiency, quicker motion, and a lower total weight.

- Robust and Long-Lasting: Its lightweight nature may deceive you. With proper alloying and processing, aluminium exhibits a remarkable strength-to-weight ratio. This means you obtain solid, resilient components that lack bulk. Additionally, it has a natural resistance to corrosion, which helps maintain the appearance and dependable performance of components in harsh conditions.

Table of Specifications Aluminium Turning Components

| Specification | Details |

|---|---|

| Material | Aluminium (Grades: 6061, 6082, 7075, etc.) |

| Diameter Range | 5 mm to 100 mm |

| Length Range | Up to 300 mm |

| Tolerance | ±0.01 mm to ±0.05 mm |

| Surface Finish | Anodized, Polished, Powder Coated, Natural |

| Machining Process | CNC Turning, Conventional Turning |

| Applications | Automotive, Aerospace, Medical, Electronics, Industrial |

| Customization | As per client’s drawing or sample |

| Packaging | Bubble Wrap, Wooden Boxes, Export Quality Packing |

Advantages of Aluminium Turning Components

- Lightweight Champion: This may be the most renowned attribute of aluminium. Due to its considerable lightness in comparison to various other metals such as steel, it is perfect for uses where minimizing weight is essential. Consider aerospace, automotive, or even portable electronics – lighter parts lead to improved fuel efficiency, quicker movement, and easier handling.

- Strength-to-Weight Ratio Wonder: Its light weight might deceive you, but don’t be fooled. The strength-to-weight ratio of aluminium alloys is remarkable. This signifies that you obtain outstanding structural integrity and durability without the extra weight. It is already quite difficult to endure challenging conditions while maintaining a slim overall product.

- Outstanding Machinability: Compared to harder metals, aluminium is relatively soft and easy to cut and shape. This results in quicker manufacturing times, reduced strain on machining tools, and ultimately a production process that is more economical. Its good machinability allows for very intricate and detailed designs to be created.

- Corrosion Resistance: Aluminium, as opposed to iron and steel, develops a protective oxide layer on its surface when it comes into contact with air. This layer serves as a protective barrier, stopping rust and additional corrosion. Aluminium turning components are ideal for harsh environments, including marine applications and outdoor equipment, without requiring extensive coatings or treatments.

- High Thermal and Electrical Conductivity: Aluminium serves as an outstanding conductor for heat and electric current. This characteristic adds to its worth in uses that necessitate effective heat dissipation (such as heat sinks in electronic devices) or dependable electrical conduits.

- Cost-Effectiveness: Although the initial costs for materials may differ, aluminium turning components prove to be cost-effective due to their machinability, lightweight nature (which lowers transportation expenses), and long lifespan resulting from corrosion resistance.

- Recyclability: Aluminium can be recycled fully without any loss of its inherent properties. This renders it a choice with high sustainability, as it cuts down waste and the energy required for producing new materials.

Types of Aluminium Turning Components

Aluminium Shafts

- These are long cylindrical components used in rotating machinery like motors, pumps, and gear systems. We supply shafts in different lengths and diameters based on client requirements.

Aluminium Bushes

- Used as a bearing surface in various machines, aluminium bushes help reduce friction and wear between moving parts.

Aluminium Spacers

- These are used to maintain space or distance between two machine parts. They come in different shapes and thicknesses as per specific applications.

Aluminium Nuts and Bolts

- Fasteners made from aluminium are lightweight, strong, and corrosion-resistant — ideal for automotive and aerospace applications.

Aluminium Flanges

- Flanges are used to connect pipes, valves, and pumps in various systems. We manufacture precision-turned aluminium flanges suitable for multiple industrial systems.

Aluminium Inserts

- These are precision components that are pressed or molded into plastic or other materials for enhanced durability.

Conclusion

Industries that emphasize lightweight design, durability, and precision are fueling the increasing demand for high-performance aluminum turning components. It’s not only about finding a manufacturer when it comes to selecting the right supplier; it’s about forming a partnership that guarantees your projects’ success. We are the best Best Aluminium Turning Components Supplier.

Aluminium is an excellent material for a wide range of applications due to its unmatched combination of strength, machinability, corrosion resistance, and versatility. In terms of converting this material into the precise components you require, Vision Turning Component is prepared to serve as your trustworthy and knowledgeable supplier of aluminium turning components. We welcome you to discover the impact of commitment to quality, cutting-edge technology, and customer-centered service. Reach out to us today to talk about your project needs and learn how our precision-engineered aluminium turning components can enhance your products’ performance and efficiency.