Aluminium Turning Components in Gujarat

Introduction

Vision Turning Component – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned components Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality.

Gujarat, India’s manufacturing powerhouse, has long served as a center for a variety of sectors. There is a continuous need for premium, precisely engineered components in a variety of industries, including electronics, medical devices, automotive, and aerospace. Aluminum turning components stand out among these as essential components because they provide a special combination of strength, light weight, and adaptability.In this thorough tutorial, we’ll go deeply into the world of aluminum turned parts, examine their many uses, explain why Gujarat is a crucial manufacturing region, and, lastly, introduce you to Vision Turning Component, a business that is genuinely making an impact in this field. We are the best Aluminium Turning Components Manufacturer.

Why Aluminium Turning Components

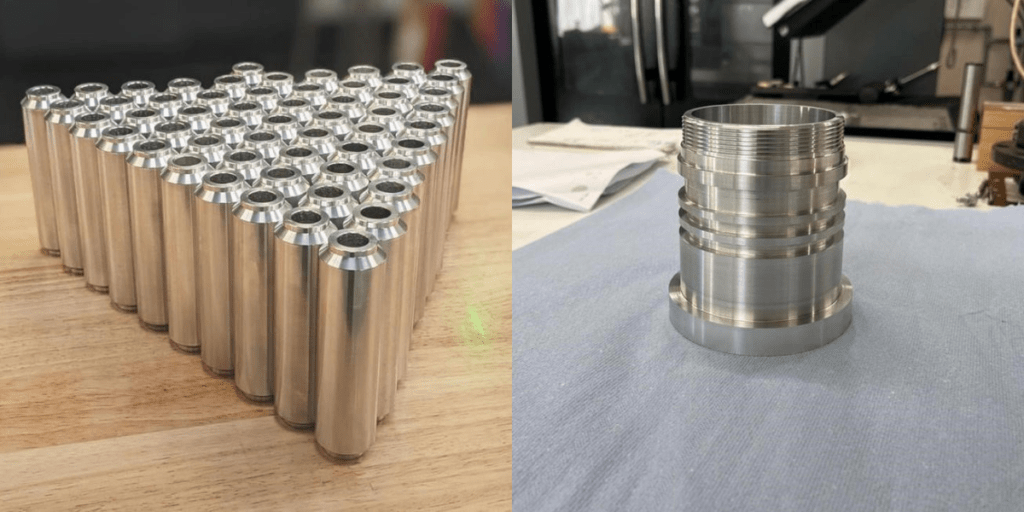

What are aluminum turning components, then? To put it simply, these are precise aluminum parts that are manufactured through a process known as “turning.” Imagine an aluminum rod or block rotating quickly on a device known as a lathe. The aluminum is then precisely shaped into the required shape whether it be a complex housing, a connector, a shaft, or a bushing—by means of a specialized cutting tool.Because it can create parts with remarkable accuracy, tight tolerances, and smooth surface finishes, this process is highly prized. However, why aluminum? Its exceptional qualities hold the key to the solution. We are the best Aluminium Turning Components Supplier.

Why Choose Vision Turning Component

- Stringent Quality Control: At VTC India, quality is not just a buzzword it’s the cornerstone of our operations. We have implemented rigorous quality control processes throughout every stage of manufacturing, from material selection to final inspection. Our facility is equipped with advanced inspection tools to ensure dimensional accuracy, adherence to specifications, and superior surface finish.

- Skilled Workforce: Our team of highly qualified and experienced technicians and engineers meticulously inspects every aluminium turning component before it leaves our facility. Their expertise, combined with our cutting-edge technology, guarantees that every component meets the highest industry standards.

- State-of-the-Art Machining: We utilize advanced CNC turning machines, which are renowned for their accuracy and efficiency. This technology allows us to engineer aluminium turning components with exceptional precision, meeting even the tightest tolerances and specifications.

- Complex Geometries: Whether your requirements are for simple cylindrical parts or intricate, complex geometries, our advanced machining capabilities enable us to produce a wide range of shapes and sizes with consistent accuracy.

- Premium Aluminum Alloys: We are aware that the quality of a component’s raw material is what makes it great. Because of this, we only utilize the best aluminum alloys, guaranteeing that our parts are robust, lightweight, and extremely corrosion-resistant. We can deal with several grades of aluminum, such as and to precisely match the needs of your application.

- Tailored to Your Needs: We believe that every customer has unique requirements. Our experienced team collaborates closely with you to understand your specific needs and provide customized solutions. Whether you need a small batch of prototypes or a large-scale production run, we have the capabilities and flexibility to deliver exactly what you envision.

- Diverse Finishes: To further enhance the appearance and protection of your components, we offer a range of finishes, including anodizing, powder coating, and polishing.

- Cost-Effective Solutions: At Vision Turning Component, we are committed to providing high-quality products at competitive prices. Our optimized production methods and efficient processes allow us to offer cost-effective solutions that deliver long-term value without compromising on the excellence of our products.

- On-Time Delivery: We understand the importance of timely delivery in today’s fast-paced industries. Our efficient production planning and dedicated logistics team ensure that your components are delivered on schedule, every time. We also offer reliable national and international delivery services.

Applications of Aluminium Turning Components

- Automotive Industry: In the relentless pursuit of fuel efficiency and reduced emissions, lightweight components are paramount. Aluminium turned parts are extensively used in engine components (e.g., pistons, valve guides), transmission systems, suspension parts, heat exchangers, and various fasteners and connectors. Their excellent machinability allows for intricate designs required in modern automotive engineering.

- Aerospace Industry: Precision, lightweight, and strength are non-negotiable in aerospace. Aluminium turning components are crucial for aircraft structures, brackets, housings for avionics, hydraulic system components, and various other parts where weight reduction directly impacts fuel consumption and performance. The material’s corrosion resistance also ensures longevity in challenging atmospheric conditions.

- Electronics and Telecommunications: Aluminium’s excellent thermal and electrical conductivity make it a perfect fit for electronic applications. Turned components are used for heat sinks to dissipate heat from sensitive electronic circuits, enclosures and housings for protecting delicate internal components (like in smartphones, laptops, and other portable devices), and various connectors and terminals for reliable electrical connections.

- Medical Equipment: The medical field demands extremely high precision, reliability, and materials that are easy to sterilize and resistant to corrosion. Aluminium turned parts find applications in surgical instruments, device housings for diagnostic equipment, and components for prosthetics. Their lightweight nature also contributes to the portability of medical devices.

- Industrial Machinery and Equipment: From heavy machinery to intricate manufacturing tools, aluminium turned components are used for shafts, bushings, gears, valves, and various other functional parts. Their durability and machinability ensure consistent performance and longer operational life.

- Consumer Goods: Beyond industrial applications, aluminium turned parts are found in everyday consumer products, including household appliances, sports equipment, and various tools, where their lightweight and durable nature enhance user experience.

- Defense Sector: Similar to aerospace, the defense industry requires robust, lightweight, and reliable components that can withstand extreme conditions. Aluminium turned parts are utilized in various military equipment, vehicles, and weapon systems.

Specification Table for Aluminium Turning Components

| Parameter | Specification Range |

|---|---|

| Material | Aluminium Turning Components |

| Diameter Range | 2 mm to 150 mm |

| Length | Up to 300 mm or as per client specification |

| Tolerance | ±0.01 mm (CNC precision) |

| Finish | Natural, Anodized, Powder Coated, Polished |

| Threading Options | Metric, UNF, BSP, NPT |

| Production Capacity | 10,000+ pieces per month |

| Certifications | ISO 9001:2015, RoHS Compliant (on request) |

| MOQ | As low as 100 pieces for custom parts |

Benefits of Aluminium Turning Components

- Lightweight, Yet Strong: Aluminium is significantly lighter than steel, typically about one-third the weight. This “strength-to-weight ratio” is a game-changer, especially in industries where weight reduction is critical, such as aerospace and automotive, leading to improved fuel efficiency and performance. Modern aluminium alloys are engineered to offer impressive strength comparable to many steels.

- Excellent Machinability: This is a huge advantage for turning. Aluminium is relatively soft and easy to cut, allowing for faster machining speeds and intricate designs with high precision. This translates to quicker production times and often, lower manufacturing costs. It also enables the creation of parts with very smooth surface finishes, crucial for components that experience friction or require a polished look.

- Corrosion Resistance: Aluminium naturally forms a protective oxide layer when exposed to air. This layer acts as a barrier, preventing further corrosion and rust. This inherent resistance makes aluminium components ideal for outdoor applications or environments exposed to moisture and chemicals, reducing the need for additional protective coatings and extending the component’s lifespan.

- Good Thermal and Electrical Conductivity: Aluminium is an excellent conductor of heat and electricity. This property makes turned aluminium components indispensable in electronic devices, heat exchangers, and electrical systems where efficient heat dissipation or electrical flow is required.

- Versatility and Wide Range of Alloys: The availability of various aluminium alloys, each with tailored properties, means manufacturers can select the perfect material for specific needs. From high-strength alloys for structural applications to highly corrosion-resistant alloys for marine environments, the options are extensive.

- Cost-Effectiveness (Long-Term): While the initial cost of raw aluminium might sometimes be higher than other materials, its benefits often lead to overall cost savings. Its machinability reduces manufacturing time, its corrosion resistance minimizes maintenance and replacement costs, and its lightweight nature can significantly impact operational expenses in end-use applications fuel savings in vehicle.

- Thermal and Electrical Conductivity: Aluminum has excellent thermal and electrical conductivity. Applications needing effective electrical transmission or heat dissipation such as in electronics depend on this feature.

Types of Aluminium Turning Components

1. Aluminium Bushes

- Used in automotive, mechanical, and electrical fittings. These are ideal for absorbing shocks and reducing vibrations.

2. Aluminium Spacers

- Used in PCB assemblies, automotive frames, and construction hardware to maintain spacing between components.

3. Aluminium Connectors

- Precision connectors used in electrical, telecom, and automation systems for strong and stable connections.

4. Aluminium Fasteners (Bolts, Nuts & Washers)

- High-quality aluminium fasteners that are lightweight, rust-proof, and suitable for marine, aerospace, and construction applications.

5. Aluminium Shafts

- Customized shafts for motors, pumps, and gearboxes, offering strength with reduced weight.

6. Aluminium Threaded Parts

- Used in valves, pipe fittings, and mechanical assemblies requiring secure threading.

7. Aluminium Housings & Enclosures

- Protective enclosures for electrical circuits and sensitive equipment.

8. CNC Aluminium Machined Parts

- Custom machined components with high accuracy for complex engineering needs.

Conclusion

Even though aluminum turning components are little and frequently invisible, they are unquestionably essential to the effectiveness and usefulness of innumerable products in Gujarat’s many different industries. They are essential due to their strength, machinability, corrosion resistance, and lightweight nature.

Gujarat’s vibrant industrial culture is demonstrated by the Vision Turning Component. They are not only producing parts; they are laying the foundation for advancement across numerous industries by continuously delivering precisely manufactured aluminum turning components with an unyielding focus on quality and customer satisfaction.