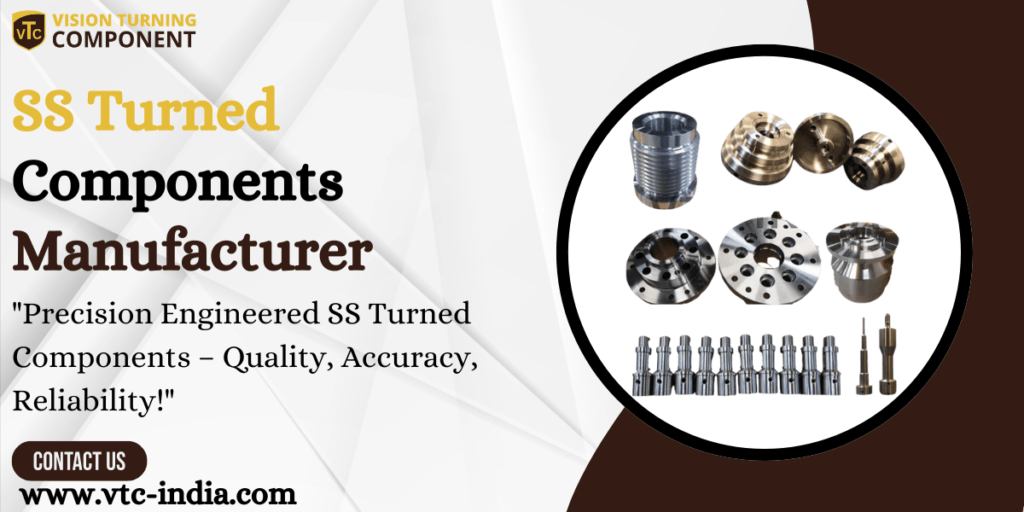

SS Turned Components Manufacturer

Table of Contents

Introduction

Vision Turning Component – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned components Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality. We are the best SS Turned Components Supplier.

It is impossible to overestimate the significance of accurate, robust, and dependable components in the complex fields of engineering and manufacturing. Stainless steel (SS) is unique among the many materials used because of its remarkable strength, resistance to corrosion, and adaptability. As a result, there is now a greater need for premium SS turned components, which are essential in many different industries.This article explores the production process, applications, and crucial function of SS turned components, delving into their complexities. For all of your precision engineering requirements, we’ll additionally emphasize why Vision Turning Component, a top manufacturer of SS turned components, is your reliable partner.SS Turned Components Exporter.

Understanding SS Turned Components

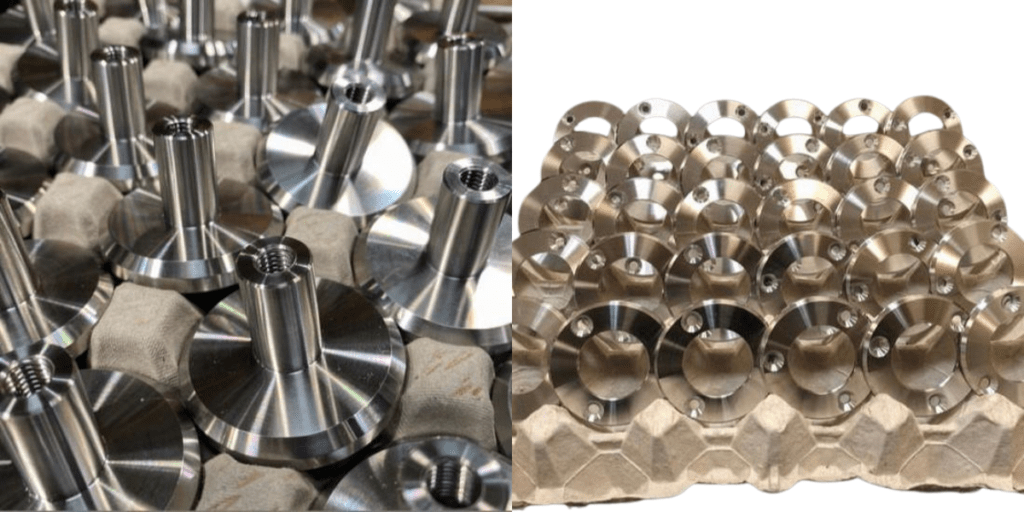

Precision parts made from stainless steel utilizing lathe turning techniques are known as SS turned components. These procedures produce components with complex geometries, clean finishes, and accurate dimensions by spinning a workpiece against a cutting tool to remove material. Stainless steel’s intrinsic qualities, including its resistance to heat, rust, and chemicals, make it the perfect material for parts that need to survive demanding applications and hostile conditions. We are the best

Why Choose Vision Turning Component?

At Vision Turning Component, we’re dedicated to giving our clients premium SS turned parts that precisely match their requirements. Our group of very talented engineers and technicians is committed to providing precisely engineered solutions. Here’s why you ought to pick us:

- Vast expertise and Proficiency: We have years of expertise producing SS-turned parts for a variety of industries. Our staff is well-versed in quality control methods, machining techniques, and stainless steel materials.

- Modern Manufacturing Facilities: To guarantee accuracy and productivity in our manufacturing procedures, we have made investments in cutting-edge CNC turning machines and other modern machinery.

- Strict Quality Control: From material selection to final inspection, we follow stringent quality control procedures throughout the whole manufacturing process.We are dedicated to providing parts that satisfy the strictest requirements for dependability and quality.

- Customization Features: We are aware that each application has different needs. We provide specialized solutions, such as surface finishing, design adjustments, and material selection, to match your unique requirements.

- On-time Delivery: We promise to deliver your components on schedule and within the allocated budget. To guarantee on-time delivery, we have a specialized logistics team and effective production procedures.

- Competitive Pricing: We provide affordable prices without sacrificing quality. Our goal is to give our clients the most return on their investment.

- Outstanding Customer Service: We are committed to establishing enduring bonds with our clients. Our staff is always on hand to respond to your inquiries and offer technical assistance.

- Variety of Materials: To satisfy a wide range of client needs, we deal with a variety of stainless steel grades as well as other materials.

- superior Equipment: We can handle complex designs thanks to our superior equipment, which includes multi-axis CNC lathes.

- Commitment to Innovation: In order to enhance our procedures and maintain our position as leaders in the field, we consistently invest in new technology and training.

Benefits Vision Turning Component

- Material Selection: Choosing the right grade of stainless steel is the first step in the procedure. Grades differ in their strength, machinability, and resistance to corrosion. Common grades that are appropriate for particular applications are 303, 304, 316, and 416.

- Preparation of the Raw Material: The chosen stainless steel is formed into bars or rods. After that, these raw materials are reduced to the length needed for turning.

- Turning Process: Using lathes or CNC turning centers, turning is the main step in the production process. To generate the desired shape, a cutting tool takes material from the workpiece while it rotates quickly. Numerous procedures, including as facing, turning, threading, drilling, and knurling, may be used in this process.

- CNC Machining: Because of their accuracy and productivity, Computer Numerical Control (CNC) machines are frequently utilized to manufacture SS turned components. Complex geometries and precise tolerances are made possible by CNC programming, guaranteeing repeatability and constant quality.

- Finishing processes: To obtain the required surface polish and dimensional accuracy, the components may go through a variety of finishing processes after turning. These procedures may involve heat treatment, deburring, polishing, and grinding.

- Quality Control: To guarantee that the components fulfill the necessary requirements, strict quality control procedures are used throughout the manufacturing process. This covers material testing, surface finish analysis, and dimensional inspection.

Types of SS Turned Components

Because of its adaptability, SS turned components can be utilized in a wide range of sectors. Here are a few popular varieties and their applications:

- Bolts, screws, and nuts are examples of fasteners. Stainless steel fasteners offer dependable and corrosion-resistant connections for machinery, equipment, and buildings.

- Shafts and Spindles: Stainless steel shafts and spindles provide exceptional strength, durability, and wear resistance when utilized in rotating machinery.

- Bushings and Bearings: In a variety of mechanical systems, SS bushings and bearings offer dependable and smooth rotational action.

- Connectors and Fittings: Stainless steel connectors and fittings, which are used in gas and fluid systems, guarantee connections that are both corrosion-resistant and leak-free.

- Valve Components: In many industrial processes, SS valve components are crucial for regulating the flow of gases and liquids.

- Medical Implants and tools: Stainless steel is perfect for surgical tools and medical implants due to its corrosion resistance and biocompatibility.

- automobile Components: Engine parts, braking systems, and fuel systems are just a few of the automobile applications for stainless steel-turned components.

- Aerospace Components: Because stainless steel is strong and long-lasting, it can be used in aerospace applications where dependability is essential.

- Food Processing Equipment: Because of its corrosion resistance and hygienic qualities, stainless steel components are frequently used in food processing equipment.

- Marine Applications: SS components offer exceptional corrosion resistance in marine situations, where exposure to seawater is a persistent issue.

Applications of SS Turned Components

Because of stainless steel’s adaptability and turning accuracy, SS turned components can be used in a variety of sectors and applications.

- Automotive: Because of its longevity and resistance to corrosion, stainless steel turned parts are utilized in engine parts, fuel systems, and braking systems.

- Aerospace: Engines, landing gear, and structural elements all require high-strength, heat-resistant stainless steel turned components.

- Medical: Stainless steel is perfect for surgical tools, implants, and medical devices because of its sanitary qualities.

- Food Processing: Because stainless steel turned parts are easy to clean and resistant to corrosion, they are utilized in food processing equipment such pumps, fittings, and valves.

- Oil and Gas: Because SS turned components can survive extreme conditions, they are utilized in drilling equipment, pipelines, and offshore platforms.

- Electronics: Electronic device enclosures, fasteners, and connectors all need precision SS-turned parts.

- General Engineering: A vast array of consumer goods, industrial machinery, and equipment require SS-turned components.

Conclusion

SS turned components, which require accuracy, robustness, and dependability, are crucial building elements for many industries. You need a partner who can meet your objectives and provide outstanding quality when selecting a manufacturer. That partner is Vision Turning Component. We are committed to giving you the best SS turned components available thanks to our experience, cutting-edge machinery, and uncompromising dedication to quality.

Vision Turning Component is prepared to fulfill your requirements, regardless of whether you require a conventional component or a customized solution. Get in touch with us right now to talk about your project and see the impact that precision engineering can have. Allow us to be the engine that propels your achievement. We are the best SS Turned Components Manufacturer in India.