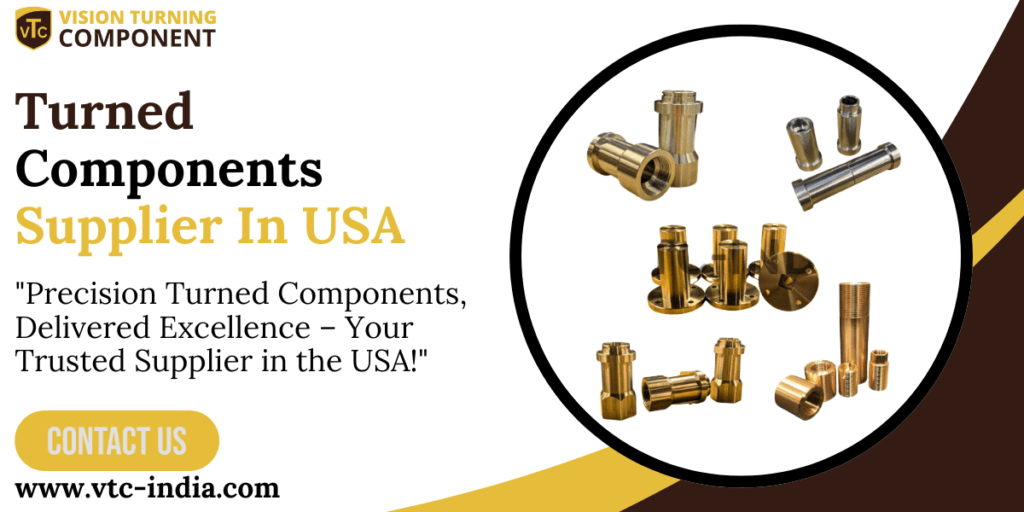

Turned Components Supplier In USA

Table of Contents

Introduction

Vision Turning Component – VTC India is the Best Industrial Components Manufacturer in Gujarat renowned as precision turned component Manufacturer and assemblies for various industries such as engineering, aerospace, medical, army vehicles, pharmaceuticals, railways, automobiles, agricultural, and machine tool industries. We are located in Jamnagar, Gujarat, India, and are well-known for our high-quality brass components used in different sectors. Our division holds an ISO 9001:2015 certification, reflecting our commitment to quality. We are the best turned components exporter.

Industries in the modern world depend on precisely built components to produce durable and useful goods. High-quality turned parts are essential to the efficient operation of many industries, including the aerospace, automotive, medical, and industrial machinery sectors.

The correct source is essential for US businesses seeking high-quality, dependable, and precise turned components. This is where the Vision Turning Component is useful. Vision Turning Component, a top supplier of turned component, is distinguished by its dedication to accuracy, quality, and client satisfaction.

What Are Turned Components?

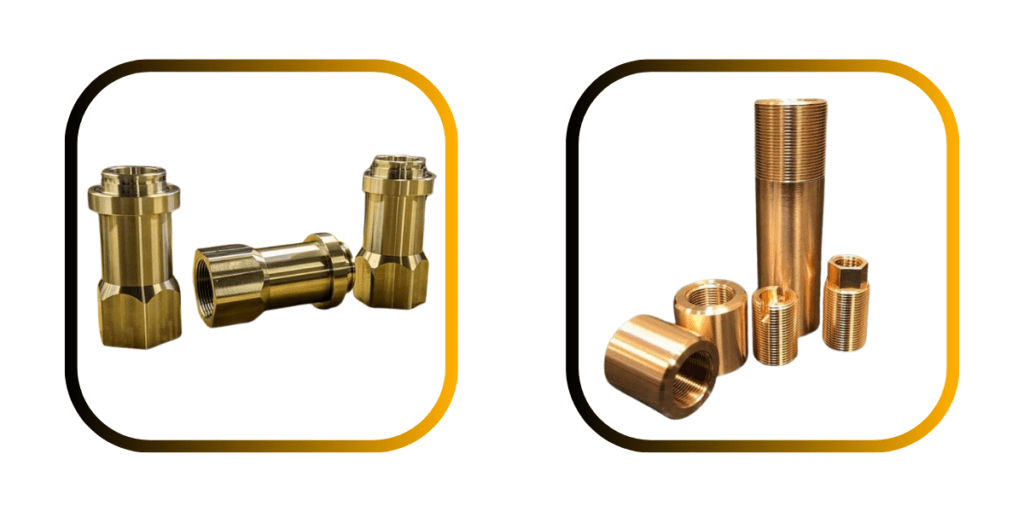

It’s crucial to comprehend what turned components are before delving further into the responsibilities of a supplier of turned components. In a nutshell, turned components are mechanical parts made by the turning process. In this kind of machining, a workpiece is rotated on a lathe while the material is shaped by a cutting tool.

Components that have been turned can be spherical, conical, or cylindrical, among other shapes. Parts with exact dimensions and tight tolerances can be produced with this procedure, which is essential for the finished product to function properly. Depending on the requirements of the industry, these parts are manufactured from a range of materials, including metal, plastic, and other specific alloys.

Why Are Turned Components Important?

For a number of reasons, turned components are crucial in various sectors.

- Accuracy and Precision: The precision that turned components provide is one of their biggest advantages. Even the smallest mistake can result in disastrous disasters in sectors like aerospace and medicine. Tight tolerances and strict quality requirements are guaranteed for these parts thanks to turned components.

- Versatility: There are many uses for turned components, which make them extremely adaptable. The options are unlimited, ranging from basic bolts to intricate mechanical components.

- High Efficiency: The turning process is perfect for mass manufacturing since it enables the quick creation of components. For enterprises that need to manufacture a lot of parts quickly, this efficiency is essential.

- Durability: Turned components are extremely durable when constructed from high-quality materials. They are resistant to severe weather conditions, elevated temperatures, and considerable deterioration.

Industries That Rely on Turned Components

Numerous industries, each with specific needs, depend on turned components. The following are some significant industries that significantly depend on turned components:

- Aerospace Industry: Turned components are used in aircraft engines, landing gear, and other critical parts that require high precision and durability.

- Automotive Industry: From engine parts to suspension components, the automotive industry relies on turned components for performance and safety.

- Medical Equipment: Turned components are used in medical devices like surgical instruments, implants, and diagnostic equipment, where precision is of utmost importance.

- Energy and Oil & Gas: Components used in drilling, extraction, and energy production require high-strength materials and precise manufacturing, making turned components ideal.

- Industrial Machinery: Turned components are used in machinery like conveyors, pumps, and compressors, which require reliability and functionality for smooth operations.

Why Choose Vision Turning Component?

Vision Turning Component need to be your first pick if you’re searching for a trustworthy supplier of turned components in the USA. With our headquarters in India, we are well-known throughout the world for providing a wide range of sectors with turned components of the highest caliber.

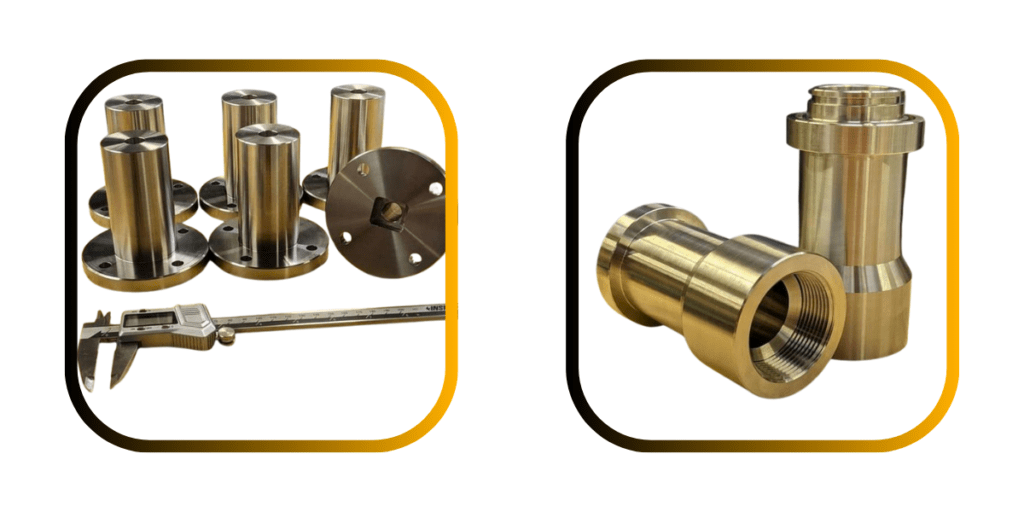

- Precision Manufacturing: To produce components that satisfy the highest standards of precision, Vision Turning Component uses cutting-edge equipment and the most recent turning technology. We guarantee that every product satisfies your requirements, whether you require conventional parts or custom-made components.

- Various Material Options: We provide turned components made of a variety of materials, such as composites, plastics, and metals including brass, aluminum, and stainless steel. Vision Turning Component is capable of providing any material needed for your project.

- Customization: Our staff closely collaborates with customers to ascertain their precise needs before offering solutions that are specifically tailored to meet those needs. We can assist you with realizing your concept if you require turned components with certain characteristics, dimensions, or designs.

- Worldwide Shipping: Despite having our headquarters in India, we offer our services outside of the country’s borders. We are pleased to transport our goods anywhere in the world, including the USA, so your company will always have access to top-notch parts.

- Competitive Pricing: We at Vision Turning Component are committed to providing premium goods at reasonable costs. We provide affordable options for both small-batch and large-scale manufacturing.

- Fast Turnaround Time: We are aware that manufacturing relies heavily on time, and delays might result in production schedule difficulties. To guarantee that you receive your components when you need them, we provide fast turnaround times on all orders.

- Assurance of Quality: At the heart of everything we do is quality. To guarantee that they fulfill the highest industry requirements, all components go through stringent quality control inspections. We take pleasure in exceeding customer expectations with flawless products.

- Team of Experts: Our group of knowledgeable engineers and technicians is an expert in the process of turning. With years of experience, they can offer insightful advice and suggestions to assist you in selecting the best project components.

- Complete Services: From design and prototype to final production and delivery, Vision Turning Component provides end-to-end services. For any of your needs involving turned components, we are your one-stop shop.

How Turned Components Benefit Your Business

There are many advantages for your company when you work with a reputable supplier like Vision Turning Component:

- Improved Product Quality: You can make sure that your finished goods are dependable, long-lasting, and practical by sourcing premium turned components. Better customer satisfaction and fewer quality control problems result from this.

- Decreased Lead Time: You can meet strict production timelines and schedules when you have a dependable supplier on your side since you can rely on prompt delivery and shorter lead times.

- Cost Savings: Vision Turning Component helps you lower production costs, boosting your profit margins, with our affordable prices and highly effective manufacturing techniques.

- Scalability: Your component requirements may alter as your organization expands. From small-batch orders to large-scale manufacture, Vision Turning Component can increase output to suit your requirements.

- Consistency: You can rely on dependable quality and performance with each order when you engage with a reliable supplier. By doing this, possible interruptions are avoided and your manufacturing procedures are streamlined.

The Future of Turned Components Manufacturing

As technology advances, the turned components business is changing as well. The manufacturing process for these parts has been completely transformed by the advent of CNC (Computer Numerical Control) turning machines. Unmatched automation and precision provided by CNC machines lowers the possibility of human error and increases total production efficiency.

We can anticipate more advancements in turning materials in the years to come, as new alloys and composites are being created for particular uses. Additionally, turning components will be crucial to the success of automation and robotics as companies depend more and more on these technologies.

Conclusion

Vision Turning Component is a reliable partner for American businesses looking for precision-engineered, high-quality turned components. We are a top supplier in the worldwide industry because of our dedication to quality, prompt delivery, and client happiness. Regardless of your industry—aerospace, automotive, medical, or any other—we offer the parts you require to maintain efficient operations. We are the best turned components manufacturer.

To find out more about our offerings and how we can help your company with superior turned components, get in touch with us right now.